Spring 2021 Design Day

Our Spring 2021 Virtual Engineering Design Day event will be held via Zoom, on Wednesday, May 5, 2021, from 1:00pm-4:30pm.

Our 2021 Design Day Booklet (PDF) provides a picture and description of all projects that will be participating in the 2021 event.

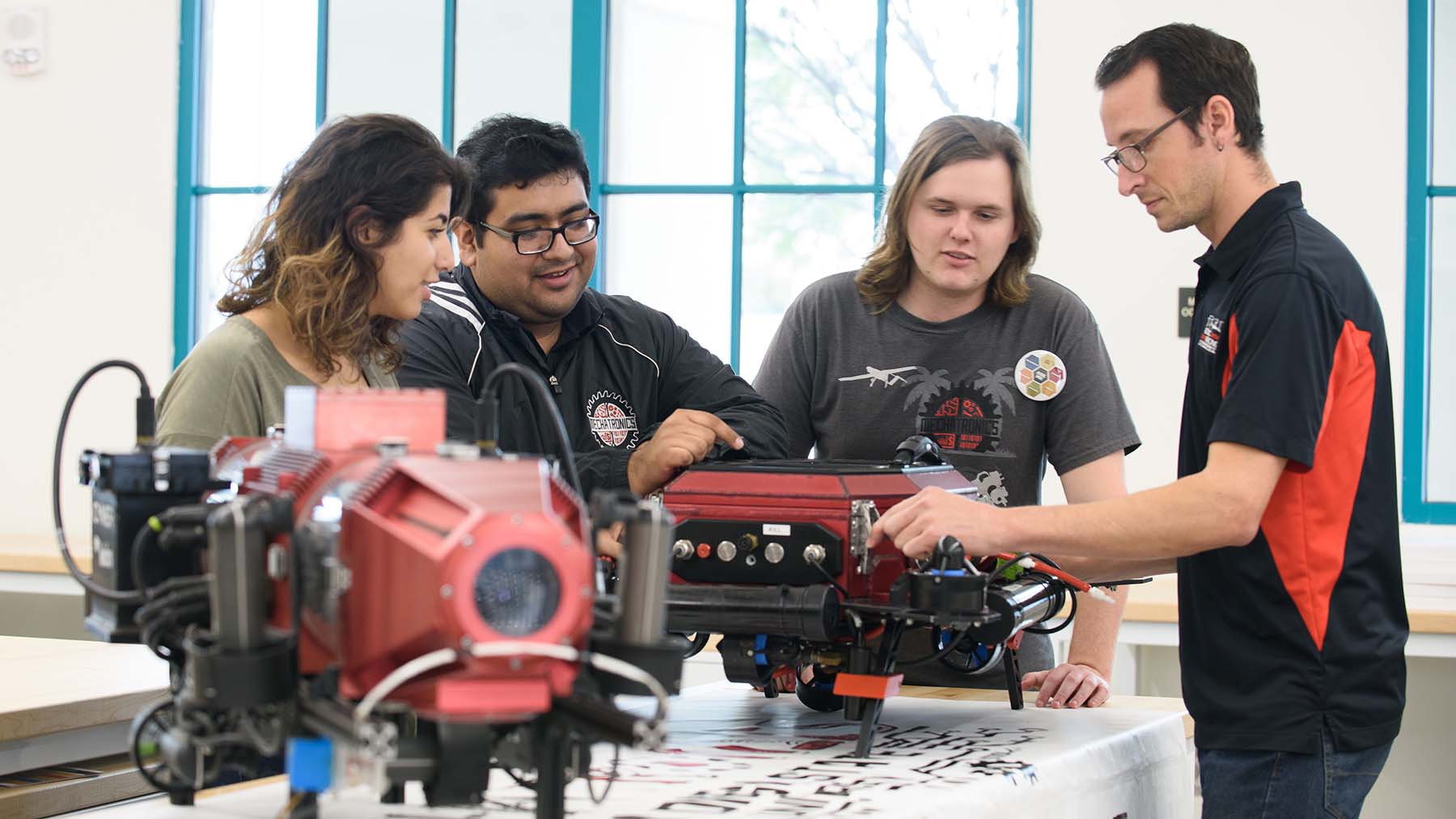

Design Day is the largest College of Engineering event and it showcases the exciting and innovative design projects that our undergraduate Engineering students conceive, design and build during the academic year. Each Senior Design classes in Aerospace Engineering, Civil, Construction & Environmental Engineering, Electrical & Computer Engineering, and Mechanical Engineering will be participating. 82 projects will be showcased at the 2021 Virtual Engineering Design Day event. Below are the Mechanical Engineering Senior Design projects that will be showcased at the event.

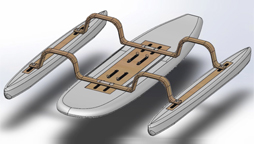

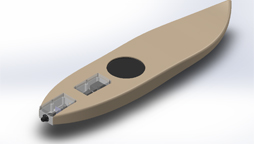

Quality of Life’s Challenger Adaptive Freedom Foundation uses an existing fleet of Wheelchair Adaptive Stand Up Paddle boards (WASUP) that have various issues and require a new solution. Team Adaptive Flow has designed and engineered a new WASUP system which accommodates 800 pounds while maintaining stability, strength, maneuverability, and welcomes all athletes. The system achieves these goals while maintaining a traditional and sporty aesthetic. Adaptive Flow’s WASUP allows easy assembly and hopes to create smiles one athlete at a time.

- Team Members: Brandon Do, Charles Malnar II, Lambert Soto, Christopher Tran Rojas

- WASUP Team Video

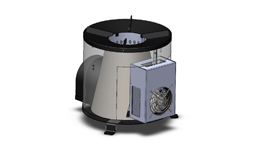

Automated microgreens growing appliance: designed to provide daily access to affordable microgreens. The project aims to provide the ideal growing environment for microgreens regardless of its surroundings. To achieve this our team developed an integrated controls system that oversees the watering, lighting, and climate of the growing environment through various electromechanical actuators, sensors, and custom PCB's. To ensure a consistent supply of microgreens to the user the device can grow up to five varieties.

- Team Members: Ali Alqaoud, Jose Baez, John Berger, Abigail Dabu, Daniel Kenner, Max Merritt, Thuyavan Sathiamurthi, Conor Vasiliadis

- Automated Microgreens Growing Environment Team Video

- Automated Microgreens Growing Environment Team Website

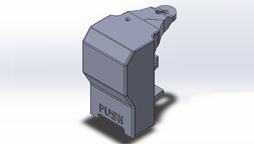

Team Pharmhouse will design and manufacture a pill dispenser that will be able to distribute a desired amount of pills to their respective days in both weekly and monthly pill organizers, including am and pm weekly containers. The dispenser will also be able to be compatible with pills of a variety of shapes and sizes, as it is common for users to take multiple unique pills per day. The design will accommodate users with impairments such as arthritis, color-blindness, and various upper extremity issues.

- Team Members: Musaed Albaghdadi, Naser Alfaresy, Jacob Martinez, Chandler Meziere, Sean Myers, Tony Nguyen, David-Paul Sabado, Jeff Smith, Micah Spence, Jennifer Thai

- Team Pharmhouse Video

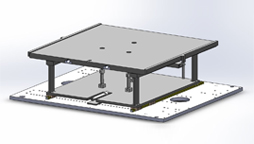

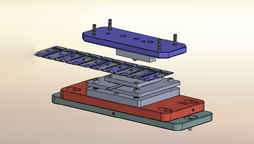

Our team was tasked with creating a tooling design that will heat and clamp a warped PCB during the dispensing process. It will be integrated into an existing Nordson dispensing machine, and must be able to move the PCB so that the machine can cover the entire dispensing area.

- Team Members: Sean Clare, Martin Cortel, Hunter Hoppis, Philip Spira

- Automated Tooling Design Team Video

The objective of this project is to design, fabricate and demonstrate a water bottle refilling station that elminates water spillage normally encountered with traditional stations. The station employs an infrared sensor to detect a bottle, along with a microphone that detects a predetermined rate of change in the cavity resonance frequencies providing key information on when the bottle is full. Once the signal is detected indicating a full bottle, a microcontroller automatically shuts off the flow of water thus preventing overflow.

- Team Members: Behymer, Ahmed Bohamad, Alberto Gomez-Flores, Lydia Keaty, Nguyen Pham, Erick Pompa, Ivan Santana, Stephanie Suarez, Mohamad Zeidan

- Water Bottle Filling Station Team Video

- Water Bottle Filling Station Team Website

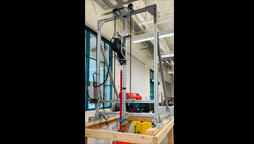

The ARES system is SDSU's submission to NASA's 2021 RASC-AL Moon to Mars Ice Prospecting Challenge with the goals of developing technologies capable of extracting water on the Moon and Mars and advancing the critical knowledge needed to further solar system exploration. ARES was designed as a prototype capable of extracting water from ice deposits buried beneath simulated lunar or Martian soil, identifying and mapping subsurface layers, and extracting water from a 600-pound ice block in a simulated off-world test bed.

- Team Members: Humood Algunaim, David Bunson, Alan Clemenson, Jesus Figueroa, Matthew Gonzalez, Jonathan Maravilla, Ryan Marmion, Brandon Mosburg, Krysta Rhodes

- ARES Team Video

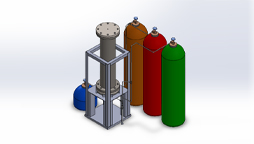

Currently, carbon particle generators use gaseous fuels like methane which are not as efficient as liquid fuels such as decane in generating carbon microparticles for solar energy absorption. Our project will utilize a laminar flame burner in combination with a pressure chamber to pyrolyze decane into carbon and hydrogen. The carbon that has been generated will be used to increase the efficiency of a solar based power generation system.

- Team Members: Ali Alqattan, Ricardo Camacho, Cesar Telles, Edward Tomassone, Brandt Walton

- Carbon Particle Generator Team Video

Ice-formation on the leading edges of an aircraft is an issue that affects the aerospace industry. Recently, there has been an increased usage of composite structures, but the thermal limits of these materials are much lower relative to more traditional aluminum structures. Therefore, a reliable means for removing ice formation is needed. This system includes heating wires embedded in the composite layers with the addition of expanded graphite to the epoxy matrix in order to increase its thermal conductivity.

- Team Members: Sarah Corduan, Prince Glick, Aldo E. Quintana, Mario Vazquez Garcia

- De-Icing System Team Video

The team has developed and performed feasibility of a new needle hub design for the next generation Dexcom device, consisting of a snap-in needle design that is more straightforward, significantly cheaper, easier to manufacture, and enables a decrease in technical failures, thus being more reliable and efficient.

- Team Members: Casey Fischbach, Sonia Goetschius, Maria Morgan, Gilbert Angel Munoz

- Dexcom Needle Hub Team Video

Dexcom Sensor Connection Process Feasibility (Video)

The production of sensors is a tricky process that can have a low overall efficiency. There are three key factors when using an Anisotropic Conductive Film to bond sensors and wires; the temperature, time, and pressure. The new design allows for accurate pressure readings with a force sensitive resistor and precise temperature control with a thermal insertion heater. The design will allow the user to determine the best bonding conditions and increase the overall efficiency of the process.

- Team Members: Brandon Cerezo, Mitchell Myers, Felipe Sales, David Jerome Valentin

- Dexcom Sensor Connection Team Video

Durable Prosthetic Knee Sleeve

Our challenger is a veteran that lost both of his legs overseas, but that has not stopped his active lifestyle. In order to keep up with this lifestyle, our team has designed, manufactured and tested a more durable prosthetic suspension sleeve to be used with his current vacuum system. By using a silicone-fabric composite and an insertable knee brace, we aim to give a longer lasting and stable suspension sleeve.

- Team Members: Aaron Eppstein, Daniel Frankul, Patrick Kelly, Thomas Laubender

- Durable Prosthetic Knee Sleeve Team Video

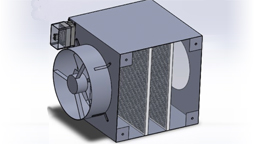

The challenge is to enable K-12 students (and university level) to be able to return to school with a reduced risk of infection of viruses, specifically COVID-19. Our team designed an affordable system that filters air and any airborne virus near a student's desk or study area without hindering the students' learning experience.

- Team Members: Justin Bernardo, Kaylin Nguyen, Ayzher Jubilee Ocsona, Damian Orozco

- Educational Seating System Team Video

- Educational Seating System Team Website

Face Mask with Active Virus Control (ECE/ME Joint Project)

This team has designed an innovative facemask that incorporates a UV light sterilization system coupled with a filter to inactivate airborne pathogens including SARS-CoV-2.

- Team Members: Victor Guzman, Brandon Hoang, Ryan Malone, David Nikiforov, Nathan Pennington, Faud Siraj, Sophia Smith, Breanna Tang, Raven Tomas, Tyler Young

- Face Mask Team Video

There is no vending machine on the market that automatically dispenses a custom granola mixture. This kiosk will allow the user to choose from a variety of granola bases and toppings through a user interface and have the ingredients mixed and delivered to them. Aztec Granola Factory is tasked with designing and manufacturing the architecture and all the major subsystems of the kiosk. This includes the 80/20 frame, ingredient storage containers, dispensing valves, and mixing/measurement mechanism.

- Team Members: Antonio Avila Ramirez, Joseph Dawisha, Mark-yves Gaunin, Marc Gordon, Winston Liew, Austin McElrone, Ezra Simpson, Sudarshan Suresh Babu, Naomi Tewolde

- Smart Granola Kiosk Team Video

This project encompasses designing, fabricating, and installing a mounting system for a fuel tank redesign to be used on a Gryoplane. This solution will be available as a kit package and components were designed to be modular. The main tank will be mounted via an adhesive-bracket system which will be attached to the keel of the vessel, with vibration dampening pads interfacing between the tank and keel. The auxiliary tanks will be mounted to the mast using a clamp and an adjustable extruded aluminum cradle with a pin bracket fastening system.

- Team Members: Miguel Carlos, Anthony Verduzco-Paz, Roberto Yee, Evan Zuleta

- Gyroplane Fuel System Team Video

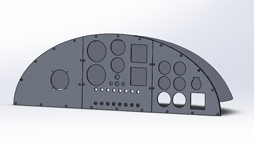

The RAF 2000 gyroplane, which was designed in the 1980’s, possesses various design flaws. The PRA has requested that some mechanical flight instruments be replaced with an electronic flight information system (EFIS) resulting in a hybrid instrument panel. Our team has been tasked with designing an instrument panel that supports the EFIS and integrates a fuel flow totalizer system.

- Team Members: Kris Ashley Gallardo, Brendan Good, Callie Johnson, Sam Reilly

- Gyroplane Instrument Panel Team Video

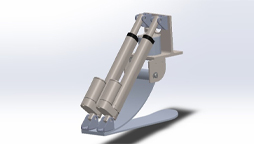

Team Power Rangers was tasked with the goal of designing and building a powered prosthetic foot to be used in the outdoors on uneven terrain in order to give the user more assistance and allow them to freely pursue their hobbies. This system will give the passive functionality of an energy return prosthetic foot while also having the capability to be powered and provide the user with additional force for push off on each step.

- Team Members: Andres Bahena, Cole Stewart, Duy Tran, Lindsey Twomey

- Team Power Rangers Video

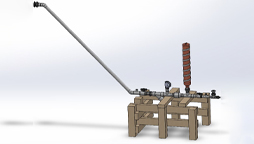

We have designed a raised platform for safe access to all surfaces of an Extreme Ultra Violet Lithography Chamber used by ASML Cymer. In addition to safe access, the platform has an assist pole that provides space for tool storage, laptop placement, and includes a writing surface. The system improves safety and efficiency while working on the chamber, but it is not limited to lithography chambers as it may be utilized for any task requiring improved height access and efficiency.

- Team Members: Saray Basulto, Roland King, Gurisher Rai, Mitchell Schick

- Lithography Chamber Team Video

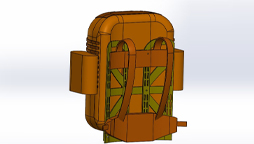

Our project goal was to develop a modular rucksack with an adjustable frame that has the ability to maintain its integrity through all missions faced by the U.S. Marine Corps 1st Reconnaissance Battalion. Our solution was the Jack pack, named after a Marine who served in the Vietnam War, this pack is every bit as resilient and ready for combat as the Marines who will be utilizing the pack.

- Team Members: Alexander Chung, Peter Love, Robert Mumma, Daniel Schneider

- Manos Team Video

The SDSU Powder Technology Lab would like to repurpose a vertical tube furnace into a hot press to consolidate materials of high strength. A lift mechanism was modified to lift the furnace into an Instron machine in order to heat the specimens during compression. Tooling was also designed and manufactured to transfer the load from the Instron directly to the specimens. A data acquisition system will acquire temperature during experimentation and record this data using LabVIEW.

- Team Members: Zachary Fruehe, Jack Gerlach, Charles Patrick Tapec, Alex Townley

- Tube Furnace Team Video

Despite dramatic technological advances in recent decades, there is still work to be done in the prosthetics field, especially in performance-enhancing, activity-oriented equipment for amputees. Our challenger is a wounded veteran with a double leg amputation. Our team was tasked with designing, manufacturing, and testing a modular prosthesis for SCUBA diving. The system's modular aspect is to aid a broad demographic of lower-limb amputees to experience SCUBA diving as naturally and effortlessly as possible.

- Team Members: Fernando Bracamontes, Lucia Carballo, Roderick Pacis, Anthony Rooks, Joshua Warden

- SCUBA Fin Team Video

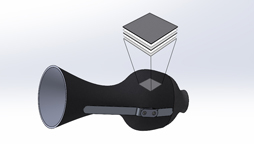

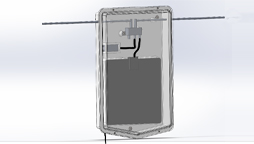

FreeTV is entering the ‘cord cutters’ market in California with a New TV Antenna. FreeTV has designed a low cost, high performance, visually inconspicuous TV antenna for residential users that can reliably receive broadcast signals from local TV stations in UHF and VHF bands. This project features engineering in electrical and mechanical design of components and assembly that is manufacturable in low to high volume production.

- Team Members: Branden Bizicki, Mark Myren, Vu Nguyen, Patrick Ong

- FreeTV Team Video

Homeowners with more than one vehicle often don’t have a second driveway for their vehicles and this requires the use of portable curb ramps. However, traditional portable curb ramps are impractical, lack versatility, are heavy, and require continuous assembly and disassembly for every use. The objective of this project is to design, fabricate, test, and implement a new portable ramp system with capabilities to support a large RV that solves all the issues previously discussed.

- Team Members: Edward Gonzalez-Sainz, Matthew Jensen, Paul Alex Trees, Antonio Vargas

- Portable Curb Ramp Team Video

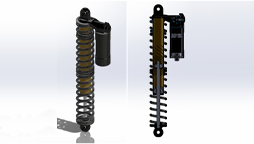

Aztec Baja SAE would like to improve their current shock absorbers to avoid harsh bottom-outs on tough terrain and to improve overall performance through research, design, and development of position sensitive technology resulting in features to be integrated with the current Fox shock absorbers on the Baja 2020-2021 car. The final design resulted in the addition of a piggyback reservoir and implementation of a grooved body, which acts as a bypass for oil flow.

- Team Members: Max Drew, James Ho, Venezia Osuna, Brianna Torres

- Shock Absorbers Team Video

The hydraulic ram pump, also known as a “hydram,” is a water pump that uses no electricity and converts a source of water from high flow and low head to low flow and high head. Using pressure surges caused by the water hammer effect, these pumps can continuously pump a portion of their incoming water to a much higher elevation. Team RamPo explored the possibilities of using a modified hydram with a thermally infused pressure chamber to generate electricity by running the exit flow through a turbine setup.

- Team Members: Grant Jung, Kenzo Maetani, Cash McCormick, Jesse Richard, Max Umland

- Ram Pump Team Video

Demand for renewable energy has led to an increase in wind power research. This project includes design, analysis, and subsection testing of a 60 ft turbine tower that may be ultimately constructed and used for research at SDSU’s Brawley Campus in the future. The tower is designed to bear a 10 KW horizontal axis wind turbine while simultaneously accommodating two 1kW or less vertical axis turbines. Testing a tower subsection serves to validate finite element analysis results and refine manufacturing/assembly plans.

- Team Members: Jeffrey Burrows, Daniel Elerding, Zachary Lang, August Stegman

- Wind Turbine Team Video

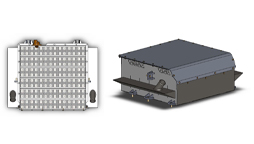

Dexcom develops Continuous Glucose Monitoring (CGM) systems, and the next iteration of their device requires a new packaging system. Our team has designed and produced a Sterile Barrier System (SBS), sealing fixture, and heat sealing recipe that is used to seal a Tyvek lid to the top of the SBS, forming a package.

- Team Members: David Bell, Sarah Gomez, Iliana Douraghi, Daniel Brandes

- SBS Heat Sealing Team Video

The objective of this project is to actively control the temperature of the batteries in the AER's racecar to prevent overheating in extreme conditions. The design includes an accumulator container with an integrated liquid immersion cooling system.

- Team Members: Kevin Alcorn, Ryan Beighlie, Kyle Hicks, Jack Mohr

- Cooling System Team Video

The current problem is that the ventilation in the EIS-106B lab needs much improvement to provide quality air flow and exchange. As it continues to be affected with the toxicity that is produced when running the laser cutting machine, 3D printer, and other tools. In response, an HVAC system is to be implemented inside the room to filter all toxic chemicals that flow within the room.

- Team Members: Yasmeen Alshiyokh, Alex Bogardus, Justin Escoto, Isaac Diaz

- EIS-106B Team Video

A motorized wave ski which gives individuals who are dealing with T4 paraplegia the ability to get through the breaking waves easily without risking their safety and giving them the opportunity to maneuver through the waves and get out to the lineup. Our objective is to design motor and controller components in order to improve balance and driving power of the wave ski, ultimately giving the individual fully independent control to comfortably maneuver through the ocean.

- Team Members: Antoni Michael Aguilar, Sydney Castillo, Sean Dapiran, Ladan Eslami

- Team Video

Access to a cheap, effective, and easily manufacturable system to sterilize medical equipment would help reduce the inequitable occurrence and severity of Health Care Associated Infections (HCAI) in non-standard medical environments, such as those in developing nations and remote military deployments. To remain accessible, it was developed with a minimal number of components that are unavailable or difficult to manufacture in developing nations. Additionally, the system does not require medical consumables to operate.

- Team Members: Spencer Bravo, Cynthia Frausto, James Reece, Alexander Smith, Gardenia Valenzuela

- Solar Sterilization System Team Video

This senior design project is tasked to design and build a Tier 4 approved, bio-fueled cook stove that incorporates Hi-Z’s thermoelectric technology to support two fans and electrical outlet. The cookstove is to be deployed to third world countries to families that use biomass as their main source of fuel. The purpose is to reduce emissions, improve efficiency and create a source of electricity in areas that have limited access to power. The system comes equipped with data logging technology to display temperature and CO.

- Team Members: Alyaa Alkharji, Josh Birkett, Agustin Cedeno-Rodriguez, Joel Edquiban, Sophia Nitkey, Jason Schwartz, Alexander Sprague, Reve Zumarraga

- Team Video

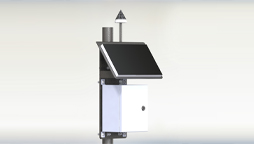

This team was tasked by the USAF at Ellsworth AFB to alert the security team at the base of an unmanned aerial vehicle (UAV) intrusion into the Ellsworth operational airspace. This team has designed a counter-UAV system capable of detecting the acoustics emitted by multi-rotor drones. In order to provide year-round surveillance, the system has been designed to utilize solar power and operate during the possible harsh weather conditions in South Dakota.

- Team Members: Brian Balsama, Rominique Borja, Blake Downey, Nick Fazio, Luke Larochelle, Christian Moreno, Isaiah Pico, Perla Ramirez, Arturo Urbano, Lilian Vu

- USAF Drone Team Video

Trash cans are not typically built to stand in high wind conditions, causing them to knock over and spill out all the garbage into the environment. The high winds at Ellsworth AFB knock the bins over and spread the trash across the base. Not only is the trash unsightly, it also has the potential to damage the aircraft on base.

The lids of the trash cans need to stay secured when tipped over in high wind conditions, but should also be user friendly for the refuse company to dump the trash out.

- Team Members: David Arushanyan, Hector Cea, Jacob Hoppe, Collin Vizina

- USAF Trash Can Team Video

To create a small ground sensor capable of covertly monitoring remote areas in real-time with wireless user accessibility. Marines require a networkable, lightweight, disposable and user-friendly device that is capable of monitoring an evolving battlespace. These ground sensors shall be dispersed by hand along key locations to detect possible adversaries by methods of acoustics, visuals and motion. This device shall provide key information to the consumer to aid in their decision-making.

- Team Members: Nicholas Balagtas, Joshua Barnard, Blake Borskey, Koa Cabling, Donnel Endaya, Raylan Jasec Gonzales, Paul Vincent Guiriba, Jakob Lepur, Henry Segura

- Team Video

The HLU-288/E Bomb Hoist is the current hoist being used by both the Marine Corps and Navy. This hoist is not time efficient while loading and downloading ordnance and other mission equipment. The purpose of this project is to develop a manually operated bomb hoist that is more time efficient than the current hoist, while also maintaining lightweight, durability, and safety requirements. This design must utilize multiple gear ratios to be switched between based on the weight of the ordnance to maximize loading speed.

- Team Members: Celine Garcia, Kyle Mahoney, Dillon Sansom, Corey Sizemore

- Team Video

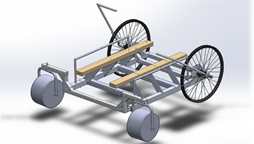

Our team has been tasked to design, analyze, prototype, and manufacture a waveski launching device that will allow our paraplegic challenger, Mr. Mark Thorton, to launch his waveski into the ocean and to land at the beach while remaining seated in order to make surf sessions easier, less complicated and more efficient.

- Team Members: Nathaniel Alihan, Andrew Fineman, Colin Knight, Antonio Mejia, Ilias Ybarra

- Team Video

The goal of this capstone senior design project is to design and manufacture a 3D printed aircraft to compete in the 5th annual 3D Printed Aircraft Competition (3DPAC) hosted at the University of Texas Arlington in July 2021. The aircraft is allowed five seconds of powered flight, after which, it competes for the longest flight duration under 30 feet of altitude. All lifting surfaces and aircraft components must be 3D printed, except for electronics, the propeller, and some hardware.

- Team Members: Matthew Larsen, Erin Mar, Tyler Rhoads, Jona Mae Tagaca

- Team Video