Spring 2020 Design Day

For the first time in the history of our event, we held our 2020 Engineering Design Day in a virtual format via Zoom on May 6, 2020. If you were unable to attend the virtual event, please see the Mechanical Engineering projects that participated below.

Please visit our College of Engineering Design Day website, which has an archive of all of our Engineering Design Day events.

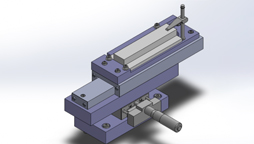

This project included the development of test methods to enable a medical device company to evaluate material properties associated with a product for continuous glucose monitoring in support of diabetes patients. The test method and associated test fixture developed helps quantify the shear forces between an adhesive patch and the patient's skin. Such information will enable improvements in device performance capabilities and ease of use for the patient.

Team Members:

- Grant Brannigan

- Max Lopez

- Jarret Nelson

- Jameel Zaki

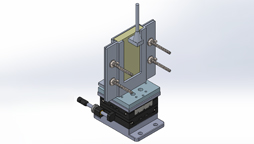

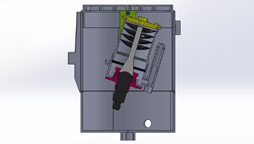

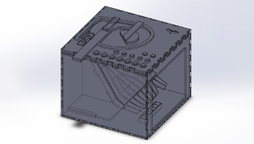

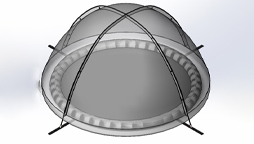

To conduct research on Lithium(Li)-ion batteries, uncontaminated samples of Li need to be analyzed with a scanning electron microscope (SEM). The sponsor’s Li samples spoil by reacting with air while transferring the sample from its container to the SEM vacuum chamber. The sponsor needs an airtight vessel to transfer the Li and then open inside the vacuum chamber once evacuated, without remote and/or electronic control, to reveal the sample.

Team Members

- Abdullah AlMutairi

- Hussain Ani

- Anthony Forsberg

- Nathan Hall

- Samuel Virgil

The project goal for Team Gyro Landers is to design a landing gear for a “Genesis Solo” G1sa 0011 Gyroplane, which is a type of rotorcraft. The group is sponsored by the Popular Rotorcraft Association (PRA), in order to create a capable lightweight “stop and drop” landing gear. The goal for the landing gear is to allow for the gyroplane to safely drop to the ground from any altitude; furthermore, the gyroplane must not tip over when travelling over uneven surfaces.

Team members:

- Yacoub Alhuwaidi

- Abdullah Alkhalifah

- Jeremiah Narcoda

- Peter Temprendola

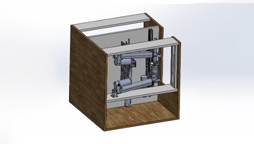

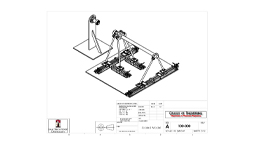

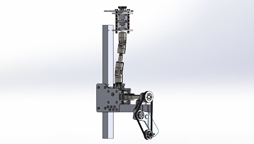

The American Society of Mechanical Engineers annually hosts student design competitions with multiple design problems. This year’s challenge is to design and build an engineering system capable of manufacturing a paper tower. The need is to develop a compact engineering system capable of manufacturing a tower, exclusively out of standard-sized sheets of paper. Design will be evaluated based on manufacturing speed, height of the tower, and the capacity to support a load.

Team members:

- Saoud Alasfar

- Khalid Almajed

- Abdulrahman Alobaidly

- Huy Nguyen

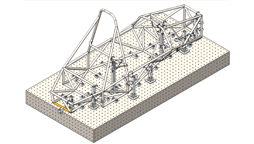

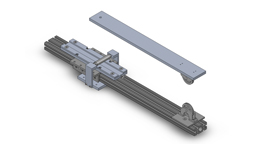

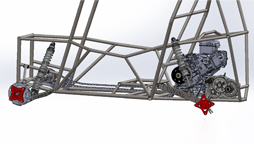

Design, manufacture, and test Aztec Electric Racing's spaceframe chassis for the 2020 FSAE competition. The team also designed a reusable chassis fixture system - a series of supports to hold all tubes of the chassis in place during welding. The chassis interfaces with all other systems and therefore was designed and built with system integration in mind.

Team Members:

- Emily Bidgood

- Brandon Black

- Cameron Curet

- Jarod Diaz

- Carmen Marques

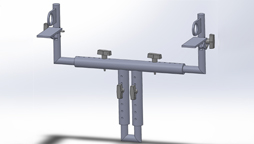

Our team was tasked with creating bicycle handlebars for a bilateral below the elbow arm amputee to enable him to once again ride a bike. Our design geometry is shaped similarly to a football field goal and is coupled with rider adjustable with pins. This allows the rider to raise, widen, or change the angle of the handlebars. The rider’s prosthetics attaches by rings at the top of the handlebars, allowing him to easily and safely connect and disconnect the handlebars. In addition, armrests are featured for comfort.

Team members:

- Matthew Buoncristiani

- Jacob Dayton

- Olivia Di Santo

- Christian Mercado

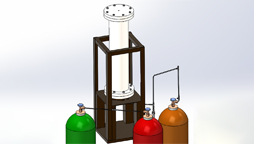

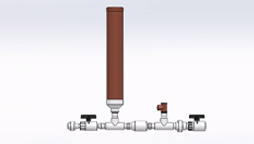

Carbon dioxide (CO2) emissions are a major contributor to global warming. This chamber has been built to aid in researching methods of decreasing atmospheric levels of CO2. The Earth’s bedrock has been identified as a possible CO2 sequestration solution, as its' high pressure and temperature environment enables the conversion of gaseous CO2 into solid carbonate. This chamber replicates the supercritical CO2 pressure and temperature conditions of 4,000 psi and 200°C required for this conversion.

Team Members:

- Sophia Dowell

- Kalina Malech

- Haley Pipkin

- Darcy Wuhrmann

The Carbon Particle Generator is a pressure chamber used to produce and funnel carbon into another device called a solar receiver. The pressure chamber contains a flat-flame burner, which is used to heat the liquid fuel up to 1500 degrees celsius. By preventing combustion, the Carbon Particle Generator can pump carbon as needed.

Team Members:

- Mohammed Alajmi

- Brennen Baron

- Jeremy Brunnenmeyer

- Sulayman Mohamed

- Eduardo Vera

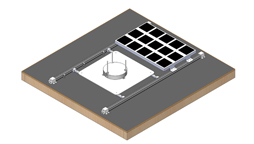

People tend to use a conventional lighting system rather than using an indoor solar lighting system. According to researchers, 30% of the electricity used in the United States is consumed by the usage of conventional lighting systems in the building sectors. Furthermore, the main purpose of the project is to reduce the high lighting power consumption caused by the usage of a conventional lighting system. An electrowetting-driven indoor solar system would be used with the method of constant light illumination.

Team Members:

- Abdualaziz Alammar

- Abdul Majeed Al Bulushi

- Abdulrahman Alfairooz

- Abdulaziz Alhazaa

- Ghdeer Alhamad

For this project, the team paired up with the medical device company Dexcom, whose main product is a continuous glucose monitoring device. The purpose of this project is to test the effects of Ethylene Oxide sterilization in combination with environmental conditioning to simulate shipping and distribution on different label and substrate combinations. Furthermore, a specialized fixture was developed to mimic the varied angle that occurs when a label is peeled off the substrate.

Team Members:

- Nicholas Greene

- Sheridan Irvine

- Mark Reyes

Dexcom would like to understand overlay patch performance, which are patches used to adhere their continuous glucose monitors on skin. Comparisons are made between a controlled bench test with the overlay adhered to a substrate that simulates skin, and an actual on body test. We have created a bench test fixture and an on body fixture. Data collected from both tests were compared to understand real life issues of the overlay patch on skin, and how patch adhesion longevity can be improved in the future.

Team Members:

- Jaber Alyami

- Brandon Lopez

- Noor Othman

- Laura Morcillo Romero

The drivetrain alignment system, sponsored by Solar Turbines, is a project that aims to develop, fabricate, and test a new way to align turbine engine drivetrains to their gearbox counterparts. Traditionally, shims are used to adjust alignment, using a process that takes up to 3 days to reach desired tolerances. The new system utilizes struts with adjustable locations and a supporting software tool to output the exact adjustments needed to achieve drivetrain alignment in less than an hour.

Team Members:

- Alexandra Gonzalez

- Holly Hagen

- Lucas Massey

- Ken Ramirez

The DX Demo - Testbed is a device that combines innovative biological processes to demonstrate the ability to rapidly decrease the time of accurate diagnosis. In the future, this product would be used to analyze blood samples to assist medical professionals to diagnose and choose successful treatment plans. Currently, the goal of this project is to demonstrate how combining standard biology lab practices with automation can advance the medical field and improve the quality of healthcare.

Team members:

- Sarah Cartwright (ME)

- David Knight (ECE)

- Anthony Lam (ECE)

- Anna Stahlak (ME)

- Garen Stein (ME)

- Savannah ter Veer (ME)

- Aaron Tran (ECE)

The Exoskeleton Biomechanics Research Platform is a mechanical device that is intended to mimic the movements of the spine during everyday activities. The exoskeleton is composed of rigid and flexible bodies simulating the vertebrae and intervertebral discs. Sensors exist within the exoskeleton that measure ranges of motion at specified locations of the spine, providing biomechanical analysis of routine movements. The exoskeleton will be incorporated as a research tool in Dr. George Youssef’s SDSU research lab.

Team Members:

- Ellie Ekstrom

- Will Hail

- Regan Lindberg

- Austin Majors

- Ryan Sutherland

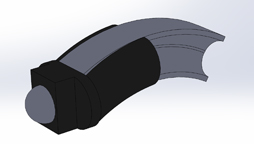

The Experimental Mechanics Laboratory at SDSU has patented an environmentally-friendly manufacturing process to create reduced-density impact mitigating polyurea foam. The current applications for this polyurea foam include reducing concussion rates via direct head impact playing football, reduced impact on the soles of runners, and reduced impact on armor plating. The need is to develop and further reduce the density in the polyurea foam so that it can be light and highly compressible for these applications.

Team Members:

- Jonathan Ethridge

- Christopher Khoury

- Antonio Maldonado

- Brandon Winsat

The goal of this project is to develop a competition-ready, four-wheel drive system for the Aztec Baja Racing Team's 2020 car. In previous years, the fastest recipe for a mini baja car has been a two-wheel drive layout. However, due to a Baja SAE rule change for the 2020 season, the team has decided to implement its first ever four-wheel drive system. This car will compete at three Baja SAE competitions in the United States against teams from around the world.

Team Members:

- Matthew Heywood

- Jacob Hicken

- Andrew Kenton

- Kyle Soto

- Paige Trevisan

This project is to develop a knee brace for skiers to assist those who ski and suffer from knee injuries or joint pain such as arthritis as well as prevent those who ski from developing knee problems.

Team Members:

- Abdullah Almulla

- Ebrahim Altaher

- Rene Arvizu

- Alejandro Ibarra

- Richard Martinez

- Jeffrey Vaquera

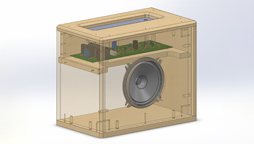

The Guitar Amplifier and Printed Circuit Board Starter Kit is a high school level STEM project intended as an introduction to electronics and engineering. The starter kit comes with the necessary components and a step-by-step procedure for the amplifier and its assembly. The assembled product is an acoustically sound and aesthetically pleasing guitar amplifier or speaker.

Team Members:

- Thomas Buchanan (ME)

- Jesus Cuen Reyes (ECE)

- Viceroy Nieva (ECE),

- Abdulla Obaidan (ME)

- Matthew Smith (ECE)

- Robert Vallejo (ME)

- Clayton Woodward (ME)

The goal of this project is to develop a system that can transmit power to the rotor blades of an autogyro. Normally, these aircrafts require a runway to spin the rotor blades and provide lift, the jump take off system will allow the aircraft to take-off vertically without the need for a runway.

Team Members:

- Dustin Drummer

- Austin Gurule

- Nikola Modrusan

- Kenneth Murillo

- Charles Winkowski

In an attempt to increase the thermal efficiency of a modern internal combustion engine, the team is building a system of effective heat recovery. With the addition of a steam system, the team is incorporating a heat-exchanger and piston driven steam engine to generate electrical power.

Team Members:

- Zachary Arellano

- Alexander Graham,

- Josue Gutierrez

- Julio Leyva

- Andy Smith

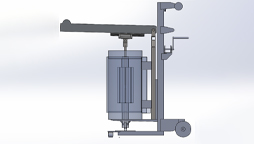

The Powder Technology Lab requires a hot press to be created from a pre-existing tube furnace and Instron press. These two components present a high temperature environment and heavy loading. These components must be joined together in order to create the hot press which will be used in experimental mechanics applications for research purposes in the laboratory. Structure and custom tooling must be designed and manufactured around the tube furnace in order to accomplish this goal in the given constraints.

Team members:

- Mesab Alasfour

- Esraa Alsaad

- Joshua Brennan

- Nnamdi Nzeadibe

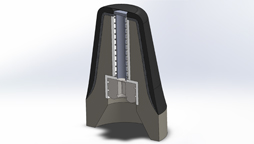

A hydraulic ram pump (hydram) is a water lifting device without the use of external power. It utilizes the kinetic energy through the water hammer effect to pump water to a higher elevation. Our objective is to create an innovate hydram that increases pump height, distance, and efficiency through the use of methods including thermal infusion to the pressure chamber, as well as cascading multiple systems. Through these improvements, our design can be utilized to pump water off-grid over a significant distance.

Team members:

- Dan Inocencio

- David Orozco Gamez

- Cameron Sacks

- Christian Solorzano

The LED laminar pool jet creates a stunningly smooth arcing jet of water up to 7 feet high & 8 feet wide that gently enters the pool or spa. The LED light allows for complete illumination of the water jet, and allows for the user to create their own adjustable breathtaking light display into their pool or spa. This particular design reduces the size of Fluidra's original Laminar Pool Jet, while also incorporating a newer and smaller LED light platform.

Team members:

- John Chillemi

- Charles Dudley

- Tristan Morales

- Jarod Ramirez

Splinter Cell is tasked to design and fabricate a Military Grade Radial Nerve Palsy Wrist Splint with the help of David Bazan, a USN Surface Warfare Officer, to provide support for individuals with radial nerve palsy while on active duty during recovery. Damage to radial nerve could cause inability to return fingers to extended position after flexion. The most important requirements include high durability, consideration for various operation environments, and a low-profile aesthetic.

Team Members:

- Connor Chaney

- Paulina Nguyen

- Sophia Nguyen

- Tri Nguyen

- Bryan Tan

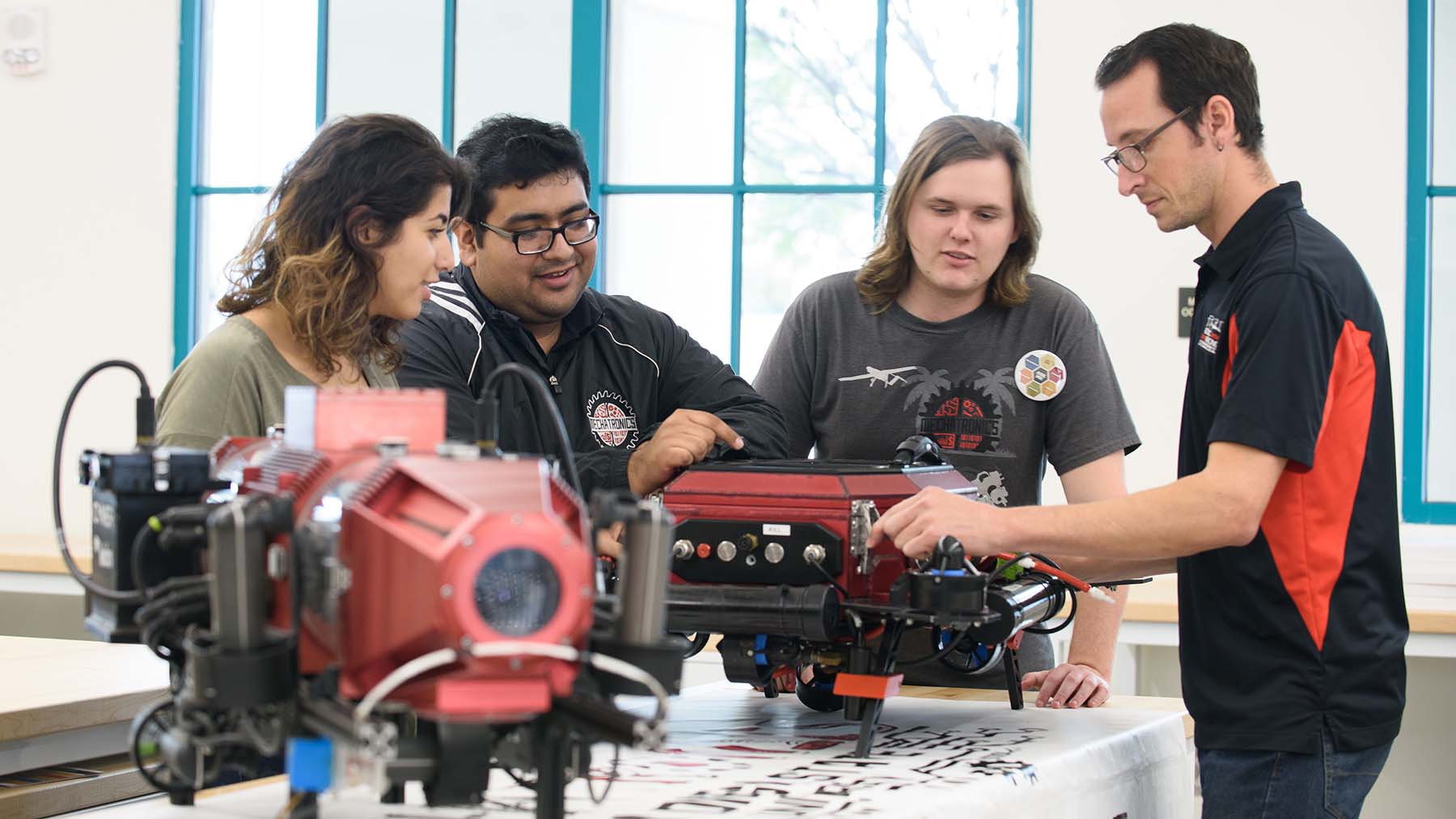

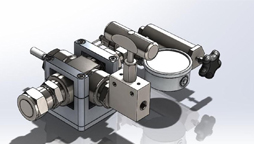

As part of SDSU's Interface Design Lab research strategy, operando optical microscopy is an essential technique that provides mechanistic insight into the behavior of complex systems. An ultra high resolution microscope with multiple analysis orientations and the capability of recording 4K video has the potential to unlock never before understood phenomena. This newly engineered system provides better performance and more customization than other commercially available systems, at a fraction of the cost.

Team members:

- Gilberto Aldrete

- Adrian Alvarez

- María Lerena

- Carlos Tellez

Our team has been tasked with designing and manufacturing a device for people with daily prescriptions that will simplify the process of organizing different types of pills and number of pills into specific days of weekly pill containers. This battery operated, hardwired device will reduce the need for fine motor skills and utilize inputs that are easy for the user to control.

Team Members:

- Erika Antonio

- Tatiana Gonzalez

- Karen Morales

- Dani Phan

- Tasha Stephens

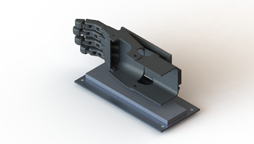

The objective of this project is to design, fabricate, test and deliver a purely mechanically driven prosthetic glove for a disabled adult. This person has a number of amputated fingers, coupled with suffering from severe arthritis. The glove will enable the person to do typical daily activities such as picking up everyday items and pursuing their hobbies.

Team Members:

- Brian Doyle

- Miguel Duarte,

- Jonathan Gaasch

- Bryan Maldonado López

- Jason Neumann

Osseointegration is a direct bone implant that allows for the attachment of an external prosthesis that provides many prosthetic users with an increased comfort and range of motion. When the prosthetic limb is not attached there is a risk of injury or discomfort to users. Our team was tasked with the design and manufacturing of a protective cap to be worn in lieu of an upper extremity prosthetic. The cap will provide protection, comfort, and support to facilitate our challenger’s return to leisure and sport activities.

Team Members:

- Kelly Bernal

- Tatyana Guerrero

- Jade Sommers

- Sophia Stepp

For the purpose of stem cell application on complex organs, stem cells must be loaded onto a tissue base, or scaffold, composed of polymer fibers like collagen. The polymer fibers in the scaffold must be aligned or patterned in such a way that they adapt to the organ and extracellular matrix, allowing the stem cells to prosper. While previous alignment methods exist, they face major limitations. Our design will test if ultrasonic vibrations can be used instead, and whether it can be done more accurately and quickly.

Team Members:

- Matthew Ariyasu

- Jordan Lee

- Kevin Lolly

- Nathaniel Schons

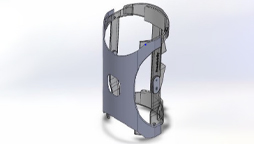

The objective of this project is to design, fabricate and test a quick release locking mechanism for a testing chamber that is used in the development of an extreme ultraviolet lithography system. This lithography system is the most advanced semiconductor fabrication solution in the world today. The quick release locking mechanism must hold a vacuum seal of at least 10^-2 Torr and be able to release and seal within 15 minutes. The design must also be able to mount a simulated metrology load measuring 10 cm.

Team Members:

- Shayne Landis

- Alexis Oyawale

- Saray Robles

- Hadeer Sekeb

The safety redesign consists of a new fuel tank, secondary fuel pump, fuel delivery system, and supporting electronics. The original system faced issues with ethanol-induced tank seam failure, and the aircraft nose pitching down under throttle. The new system addresses these issues while improving fuel level monitoring, accommodating auxiliary fuel payloads, and creating flexibility for different powerplant and auxiliary tank configurations.

Team members:

- Francisco Carvajal

- Michael Chiavacci

- Steven Parker,

- Cody Rahders

RV ARMS is a modular mounting system that holds roof accessories for recreational vehicles. The mounting system is able to be secured to all types of RV roofs, in addition, it is able to accommodate the hundreds of different types of roof mounted accessories that are currently out on the market today such as solar panels, wifi antennas, and satellites.

Team Members:

- Martin Ahumada Padilla

- Daniel Gutierrez

- Austin Halog

- Miguel Loza

- Bailey Ward

Thrombosis is a disease that causes blood clots inside blood vessels and leads to serious health risks. Dr. Xu, an Asst. Prof. of ME Department, is researching a new way of removing the clots using a Rotating Magnetic Field (RMF), instead of invasive surgery. Our team was tasked with designing, building, and testing a RMF device. The design accommodates a specimen, placed in the center of the RMF, and it’s observed via a microscope. Our team used a 2-Axis Helmholtz Coils model to build the RMF.

Team Members:

- Bashar Ablahd

- Blake Haslam

- Jeffrey Johnson

- Raid Yousuf

CubeSats are satellites that are standardized to a 10x10x10 cm volume. The goals of this project are to: (1) research and record the 3D printing process using the provided 3D printer and flexible filament to produce a document that has detailed steps on 3D printer operation, and (2) develop a fully mechanical 3D-printed self-deployable panel system that increases the surface area and is compatible with the sponsor’s custom CubeSat design using the techniques researched. All the components must be 3D printed.

Team Members:

- Fahad Almarzooqi

- Samuel G. Bumatay Jr

- Jeffery Leigh

- Brandon Pires

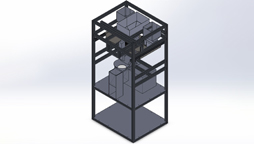

The goal of this project is to design, analyze, build, and test a machine that allows customers to select the toppings of a granola that is then mixed and distributed straight to them, all within a short amount of time. The Smart Granola Kiosk produces 20 one-pound servings of customizable granola made up of a base granola and multiple different toppings. The final production model of this kiosk would be utilized in a grocery store.

Team Members:

- Anthony Alkatib (ME)

- Thomas Durso (ME)

- Tristan Kaskoun (ME)

- Miles Kiefer (ME)

- Wenjie Kuang (ECE)

- Jiuzhang Peng (ECE)

- Gustavo Torres (ECE)

- Austin Whitaker (ME)

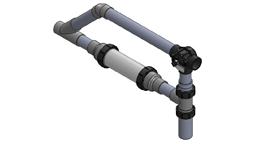

The Total Dissolved Solids Filtration System reduces the amount of calcium present in the water of saltwater pools while keeping sodium levels constant. Calcium builds up in pipes and on the walls of the pool and can only be removed by draining the pool and cleaning the calcium manually. Sodium, however, is necessary to create chlorine to keep the pool water clean. This system lowers calcium levels in the pool with each cycle so pool owners no longer need to drain their pools for cleaning, saving time, money, and energy.

Team Members:

- Nick Aiello

- Alejandro Del Castillo

- Brian Milner

- Alex Smith

The team designed, built, and tested a device to boost the quality of life for a bilateral prosthesis user who is unable to use most types of touchscreens effectively due to a lack of dexterity and incompatible point of contact. The device is non-invasive, and enables the user to effectively interact with every touch screen device found in the real world with ease.

Team Members:

- Harrison Clark

- Jacob Hoffer

- Brandon McGoey

- Steven Schneider

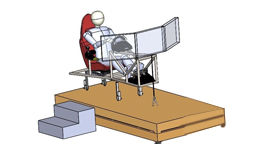

VRoOoOm is a team of mechanical engineering students who have been tasked with creating a motion simulator for driving and flight simulation games, sponsored by the Themed Entertainment Association on campus. It features a F1 style race chassis driven by linear-actuators, and a VR headset for added user experience. The main challenge of this task is to make the actuators move the chassis in a way that best tricks the user's inner ear to make the simulation feel as realistic as possible.

Team Members:

- Abdrhman Binsheha

- Noah Braman

- Julia Gurfinkel

- Kim Saldana

There are 785 million people who do not have access to an improved water source, according to the World Health Organization. With 40% of the world’s population living near the coast, many of these people have access to saltwater but have no way of making this water potable. The Condensation Organization has designed a device that aims to solve this problem using nothing but the power of the sun. Portable, durable, and simple, the water desalination tray provides an innovative solution to people in need.

Team Members:

- Daniela Cantor

- Jacob DeBartoli

- Mike Hoving

- Daniel Verga

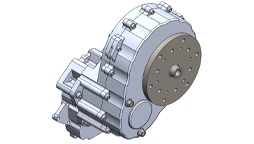

Team Aztec Flight was tasked by Popular Rotorcraft Association (PRA) of San Diego to adapt an alternate engine to replace the current expensive 2-stroke engine used by most gyroplanes. By using a less expensive 4-stroke engine it allows the hobby to become more affordable, while increasing the powertrain reliability. To adapt the 4-stroke engine, Team Aztec Flight designed and manufactured a reduction drive gearbox capable of handling the 80hp of the motor while reducing the engine output from 7,700 RPM to 3,000 RPM.

Team Members:

- Dillon Devore

- Duong Nguyen

- Daniel Templeman

- Jose Thompson

- Kyle Ryan

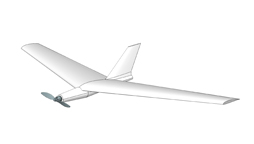

The goal of this capstone senior design project is to design and manufacture a 3D printed aircraft to compete in the 4th annual 3D Printed Aircraft Competition (3DPAC) hosted at the University of Texas Arlington in July, 2020. The aircraft is allowed five seconds of powered flight, after which, it competes for the longest flight duration under 30 feet of altitude. All lifting surfaces and aircraft components must be 3D printed, except for electronics, the propeller, and some hardware.

Team Members:

- Mitch Mahowald

- Steven Malley

- Jonathan Navarrete

- Brian Sperry

The goal of this capstone senior design project is to design and manufacture a 3D printed aircraft to compete in the 4th annual 3D Printed Aircraft Competition (3DPAC) hosted at the University of Texas Arlington in July, 2020. The aircraft is allowed five seconds of powered flight, after which, it competes for the longest flight duration under 30 feet of altitude. All lifting surfaces and aircraft components must be 3D printed, except for electronics, the propeller, and some hardware.

Team Members:

- Brian Bowling

- Taylor Burgess

- Ally Hardy

- Zakary Harrison

- Connor Hill

The goal of this capstone senior design project is to design and manufacture a 3D printed aircraft to compete in the 4th annual 3D Printed Aircraft Competition (3DPAC) hosted at the University of Texas Arlington in July, 2020. The aircraft is allowed five seconds of powered flight, after which, it competes for the longest flight duration under 30 feet of altitude. All lifting surfaces and aircraft components must be 3D printed, except for electronics, the propeller, and some hardware.

Team Members:

- Kevin Baca

- Aaron Cordoba

- Brenden Edwards

- Jason Locko