Fall 2020 Design Day

Our Fall 2020 ME Senior Design Day was in a virtual format via Zoom on December 10, 2020 from 1:30pm - 4pm. Feel free to visit our Spring 2020 Senior Design Day webpage for last semester's projects.

This testing rig performs NASA's Standard 6001B Test 1 which determines if different types of materials are safe for space travel based on their ability to self-extinguish when ignited. Two vacuum chambers stack on top of one another and house many other sub-assemblies required to meet the test requirements. The bottom chamber contains two air inlet assemblies to help blow the smoke and small particulates out. In order to get the additional data, the test rig is outfitted with the following data acquisition sensors: a load cell, a pressure sensor, a thermocouple, thermistors, a radiometer, and a camera.

- Team Members: Jarred Druzynski, David Fredriksson, Brandon Huffman, Alexander Poirier, Joseph Templeton

- Team Flame Propogation Video

The goal of this project is to develop an Organic Rankine Cycle (ORC) that serves as a proof-of-concept for generating power from waste heat extracted and recovered from Icarus RT’s solar array.

- Team Members: Jose Castellanos, Carlos Duran, Angelina Forzisi, Cristian Hernandez, Corina Lard, Christopher Oyuela

- Team Icarus RT Video

The objective of this project is to design and to manufacture a lithium processing chamber.

- Team Members: Jack Bowen, Mike Johansen, Ilze Sarma

An automated, machine vision sorter that sorts marker bands based on color, utilizing a Pixy2 Camera. This sorter is designed to be interchangeable with a Keyence XT-24 3D scanning camera, capable of measuring band length tolerance. In addition, this sorter will allow a bulk amount of marker bands to be automatically sorted into separate containers.

- Team Members: Jason Agtina, Roselynn Conrady, Theresa Escolano, Nathan Fosgett

- Team Marker Band Sorter Video

- Team Marker Band Sorter Website

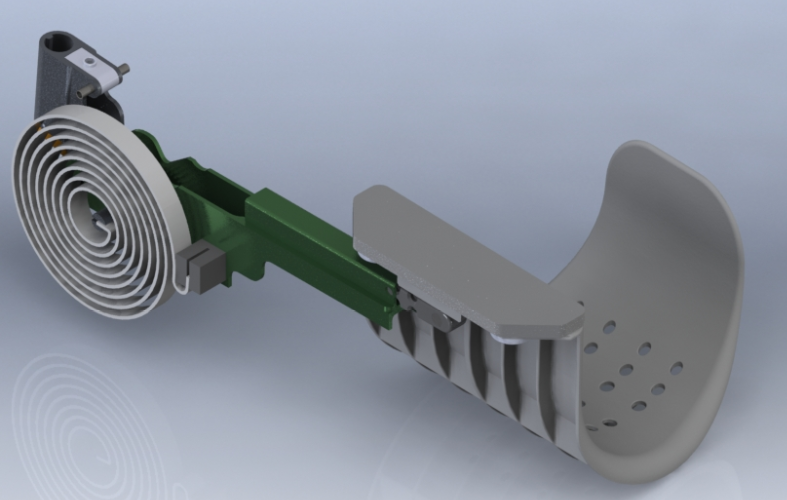

The goal for this project was to create a variable moment system using non-circular gears that functioned the same as Levitate Technologies’ current design, which utilizes tension springs and pulleys to achieve a higher cycles till failure. The cables for the pulley system were the first to fail, and would not meet a satisfactory amount of cycles. The use of gears would eliminate the need for cables, increasing the lifetime of the product and reducing its size . Using Matlab, the group was able to design a set of non-circular gears the would operate from 0 to 162 degrees.

- Team Members: Patrick Fleckenstein, Naufal Hidayat, Freddy Rivas, Noah Stanley

- Team Moment Manipulating Arm Video

NIWC’s Unmanned Maritime Vehicle (UMV) Lab is currently using Remotely Operated Vehicles (BlueROVs) to serve as low-cost Autonomous Underwater Vehicles (AUV). The BlueROVs are deployed by hand off a kayak or small boat alongside an Unmanned Surface Vehicle (USV) used to remotely communicate with the BlueROVs. The UMV Lab asked for a Multi-AUV Deploying system that will attach to the pontoons of the USV. This was accomplished by creating two identical systems that are activated by a single remote and are attached on opposite sides of the USV. Each system deploys a single BlueROV at a minimum distance of 20 meters.

- Team Members: Gabriella Garcia, Analie Samawi, Garry Valdez, Remmy Wilkinson, Max Yant

- Team MADS Video

A vertical-axis hydrokinetic turbine capable of producing at least 1 volt from water flow speeds down to 0.3 m/s at an operational depth of 15 meters.

- Team Members: Cameron Alegria, Andre Camunas, Evan Johnson, Ivette Silva, Tremaine Sorge

The team was tasked to create a device that allows users with neuromuscular disorders and injuries such as amputation and hemiplegia, to independently manipulate push turn pill bottles. The device is portable, making it easy for clients to take their medications when traveling or while completing daily tasks. The design of this device is purely mechanical and functions without the use of any batteries.

- Team Members: Daniel Campas, Claire Santos, Matt Schierman, George Sosa, Kyle Williams

- Team Video

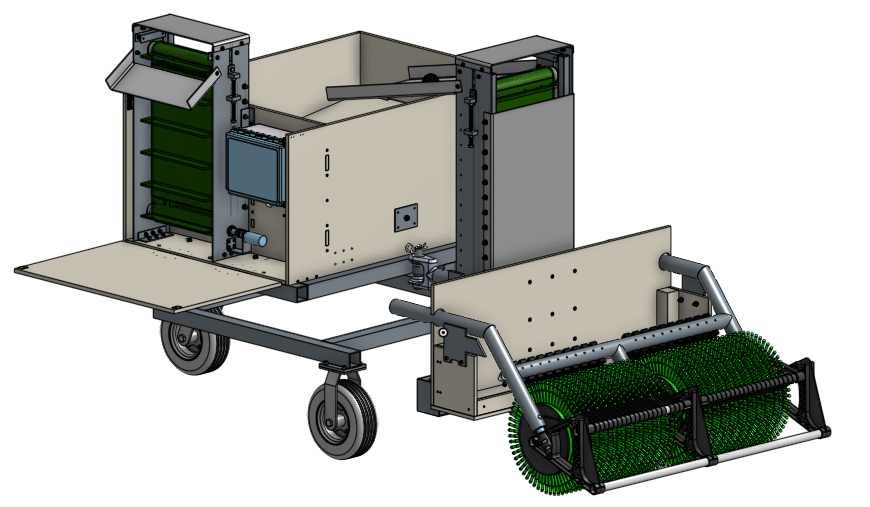

The project goal for our team is to create a mechanical system attached to an AGV to collect golf balls from a driving range. Our team paired with Otterbotics to add three subsystems to their self-driving vehicle. Our design allows for autonomous operation while collecting 1,000 golf balls in a single run. Once the bin is full, the AGV returns to the set point and distributes the balls evenly into external collecting bins.

- Team Members: Eric Gillhaus, Scott Halverson, Zach Hewitt, Liam Kerrigan, Mikey Swan

- Team Video

The objectives of this project are to design and build a production version of FRED (Floating Robot for Eliminating Debris) that can be feasibly built by ocean conservationists across the world to support Clear Blue Sea’s mission of cleansing the oceans of plastic solution. Our project is 10 foot pontoon robot that is able to be remote controlled from up to a half mile from the shore. The design consists of a conveyor belt system that dips into the ocean and brings surface level debris to a bin on the aft. All systems aboard are powered by batteries which are charged by two solar panels atop the vessel.

- Team Members: Calvin Dixon, Nick Feiner, Matt Kersman, Jason Waas

- Team Video

The goal for this project is to design a robotic walker that is in the format of a two-wheel Segway with internal self-balancing mechanism.

- Team Members: Victor Hernandez, Minh Hoang, Sam Kearns, Isaiah Oropeza

- Team Video

Controlled Thermal Resources is working on optimizing a geothermal power plant to be built in the Salton Sea geothermal field. A simulation was developed to accurately model the piping system of a similar plant. This allowed us to visualize and test the effectiveness of different piping solutions. A comparison between the current system with cement lined carbon steel, and a system with titanium clad steel was explored.

- Team Members: Marwa Abduljabbar, Kris Gaard, Nathan Gibfried, Travis Ryan, Joe Stephens

- Team Video

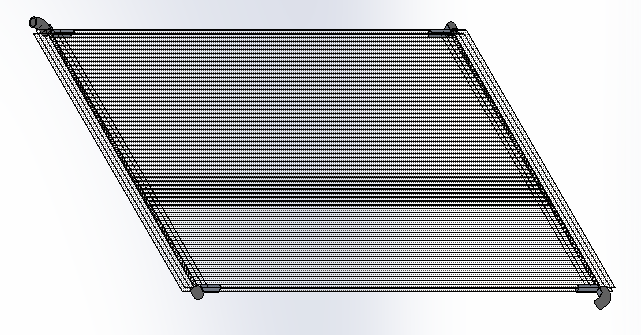

Our team was tasked by Icarus RT, Inc. to fabricate novel heat extractors for use in extracting waste heat from the surface of photovoltaic (PV) panels to be converted back into usable energy. Throughout their daily operation, the surface temperature of PV panels can vary greatly, often into temperature ranges that cause the PV panels to be less efficient. These extractors would allow the PV panel surface temperature to remain in the highest efficiency temperature range, while the heat from the working fluid can be converted into energy for use on-demand

- Team Members: Alora Aguilar & Christian Ramirez

- Team Video

To build a low-cost pyrheliometer and its tracking system

- Team Members: Tiare Corral, Bryan Ikeda, Yadira Velez

The UAV Porta-Launcher was built to launch an Opterra 2-meter drone for NAVWAR. It can be launched remotely, collapsed and transported with ease, launched at adjustable speeds between 10mph and 50mph, launched at adjustable angles between 10 and 30 degrees, and weighs just over 50 pounds.

- Team Members: Fernando Casas, Austin Clements, Patrick Greene, Joseph Mazzeo, Ayendra Subasinghe

- Team Video

Our team was tasked with designing a system to unroll a mat on the ocean floor with a total area of 100m2, for the purpose of deploying a microbial fuel cell that generates electricity from bacteria designed by our sponsors. In order to do this our team designed a pneumatic system that unrolls the mat using hoses that are filled with pressurized air.

- Team Members: Yousef Alsahli, Parker Bailey, Abhishek Pandya, Mark Sutton

- Team Video

To build a camera housing with a shutter/wiper for underwater imaging

- Team Members: Brayden Koster, Geroge Reynolds, Clayton Staples, Emmanuel Vega

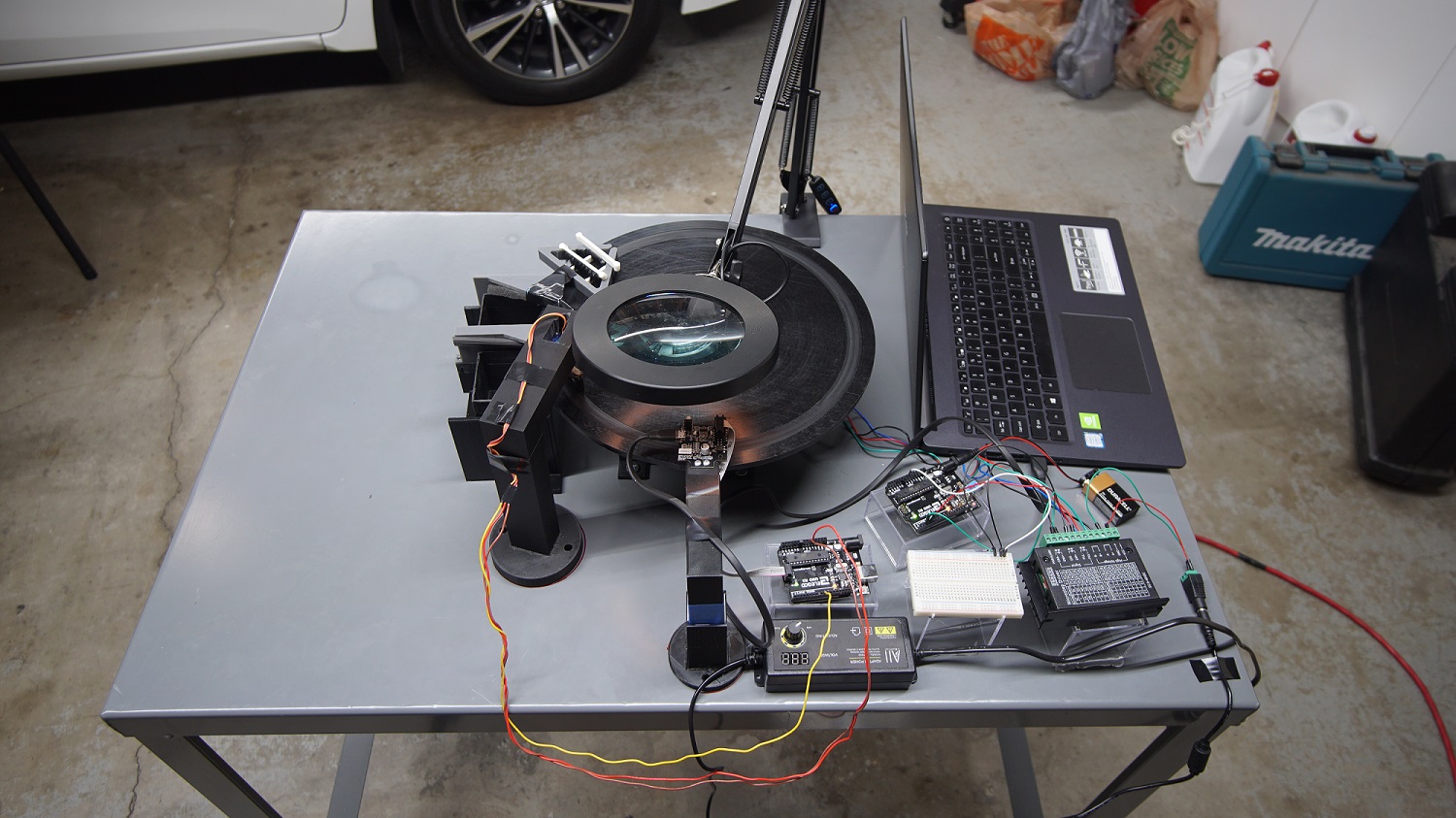

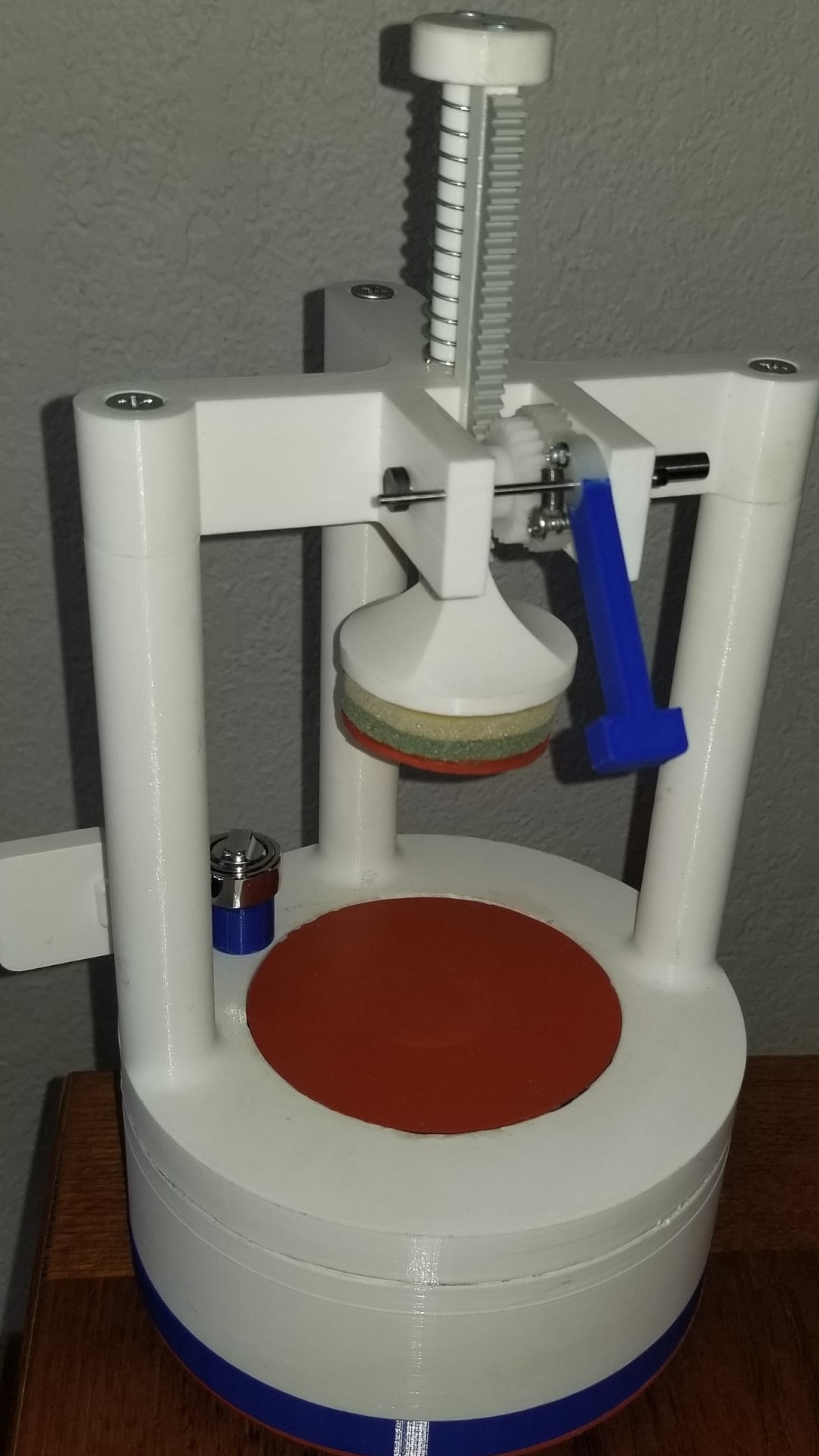

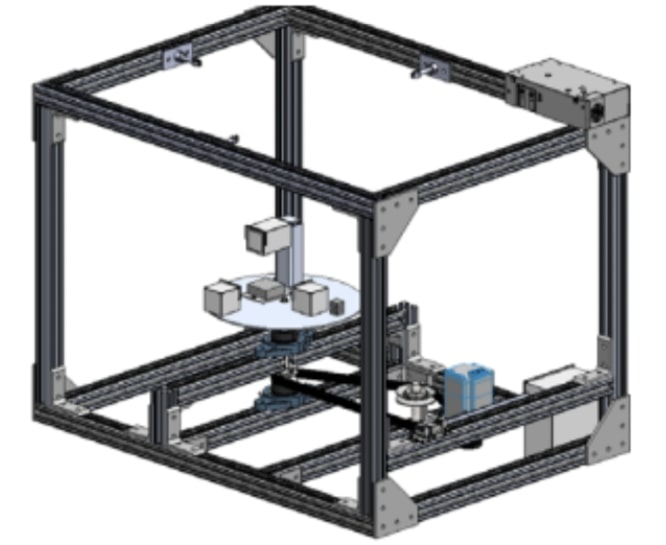

Rotating Disk Cellular Solid Testing Apparatus

Current mechanical testing for materials used in impact mitigation neglects the effect of rotational acceleration, a common factor in concussions. The objective is to build a test apparatus capable of spinning elastomeric foam samples at variable speeds up to 3000 RPM based on the experimentalist command while capturing digital images of the deformed surfaces. Ex-situ digital image correlation will be used to quantify the in-plane strain components, assessing the effects of rotational acceleration on the foam efficacy.

- Team Members: Nicholas Agtual, Madison Anderson, Dylan Lawrence, Kyle Mesch, Derek Nunotani

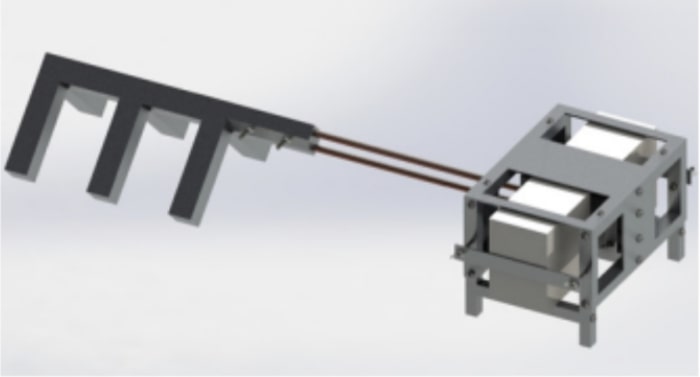

Thermoelectric Power Generator

Team Hephaestus was tasked by SDSU Mechanical Engineering Department’s Chair, Dr. Abraham, to create a sustainable power generator through the use of Thermoelectric Devices. The team has crafted a product that will use the high temperatures of a traditional campfire to distribute the heat into two Thermoelectric Modules through a heat exchanger. The TEMs will be used alongside two Cooling Units to produce a suitable temperature difference to charge a 14.8 V battery, which can charge a slew of electronic devices.

- Team Members: Andres Cardenas, Dalaney Conte, Bryce Horton, Mathew Tivey, Caroline Yu

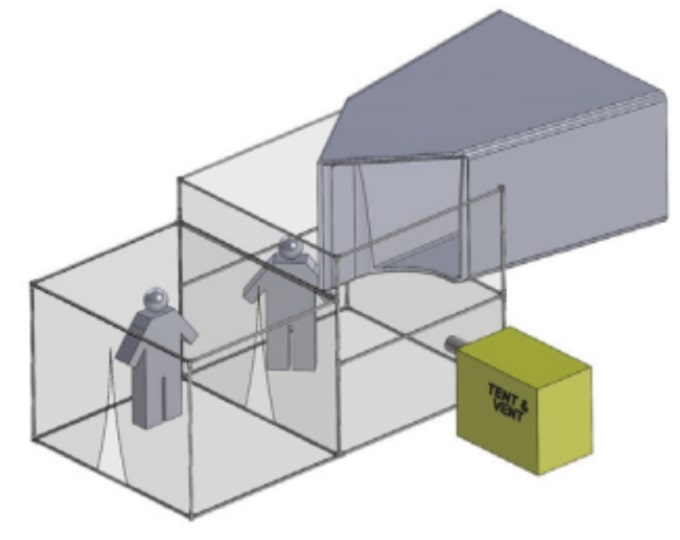

USAF B-1B Biohazard Compliant Nacelle Finishing Structure

This project provides the Ellsworth USAF with a portable/reusable bioengineering compliant finishing structure used for the nacelles of the B-1B aircraft. This ready-to-use product solution eliminates a major safety hazard to the USAF team. Key features of the finishing structure include; collapsibility, height variability and a separate enclosed decontamination room. The PVC structure is easy to procure, cost effective and architecturally adaptive for other aircraft.

- Team Members: Eric Apgar, Travus Clark, Hernan Velazquez Munoz, Daniel Murillo, Joshua Pasco

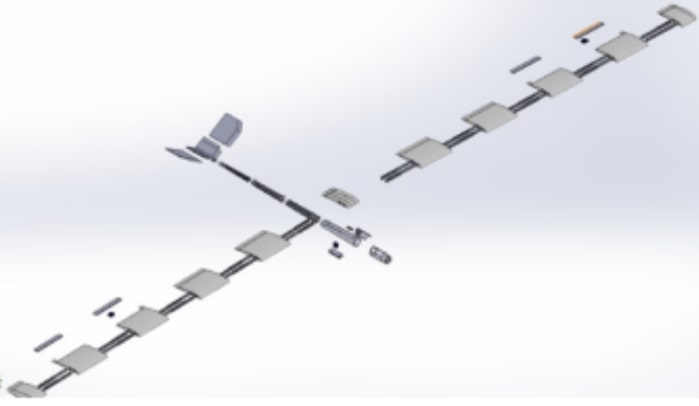

3D Printed Aircraft Competition

The Hot End Aeronautics team has designed and manufactured a 3D printed fixed-wing aircraft with the goal of prolonged flight to compete in the 3D Printed Aircraft Competition (3DPAC) hosted by California State University, Los Angeles. The project guidelines call for an aircraft that can glide the longest with a safe propulsion method for 8 seconds. All components must be 3D printed other than the electronics within the aircraft. The aircraft shall be designed as a glider in order to perform competitively.

- Team Members: Alexandre Balensi, Alexander Brown, Josh Gipson, Henos Hussien, Matt Owens

3D Printed Aircraft Competition

This team performed research, analysis, and testing to design and manufacture a fully 3D printed RC aircraft with the purpose of winning both the Most Innovative Design and Longest Duration of Flight awards in the fixed-wing category at the 3D Printed Aircraft Competition to be held in May at Cal State Los Angeles. All lifting surfaces and aircraft components must be 3D printed, except for electronics, the propeller, and some hardware. The aircraft is allowed to be powered for only 8 secs and must fly under a 30 ft altitude.

- Team Members: Drake Campo, Oscar Correa, Xavier Major, Ben Saldana, Kenton Williams