Spring 2023 Design Day

Our Spring 2023 Engineering Design Day event will be held on Thursday, May 3, 2023, from 1:00pm-4:30pm in Montezuma Hall in the Aztec Student Union.

Design Day is the largest College of Engineering event and it showcases the exciting and innovative design projects that our undergraduate Engineering students conceive, design and build during the academic year. Each Senior Design classes in Aerospace Engineering, Civil, Construction & Environmental Engineering, Electrical & Computer Engineering, and Mechanical Engineering will be participating. 73 projects will be showcased at the 2023 Engineering Design Day event. Below are the Mechanical Engineering Senior Design projects that will be showcased at the event (More details of individual projects will be available as the event draws closer).

Design Day Projects

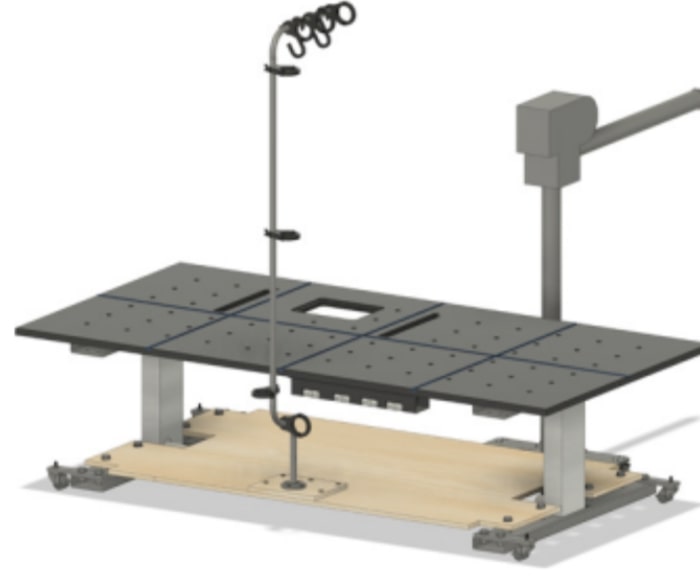

SSG Christopher Walker experienced the loss of both arms, his left leg, and many other injuries from an improvised explosive device in 2012. After recovery, he picked up woodworking but after nine years, his setup still does not accommodate a wheelchair amongst other limitations. To increase safety, capability, quality, and speed, Team Benchwarmers created: a height-adjustable bench that allows sitting and standing, shelving for better tool access, a crane lift to move material, and an arch arm to safely manage cords.

- Team Members: Nyah Brooks, Courtney Earley, Malachi Enguancho, Sam Griffith, Cody Pennefather

- Team Benchwarmers Video

The team completed research, design, analysis, and manufacturing of an avionics rack for General Atomic’s MQ-9 Reaper Drone. The avionics rack will support a Low Earth Orbit (LEO) antenna, modular Line Replaceable Unit (LRU) system and have an active cooling system. The avionics rack was designed to fit in the space of the legacy geostationary antenna being replaced by the LEO antenna.

- Team Members: John Callaway, Brendan Le Veille, Vincent Rios-Austin, Brennan Rodenburg, Lincoln Tadewald

- Team Reapers Video

The ARGUS III Remote Wildfire Sensing Program consists of a 10 person team tasked to design and create a functioning device that will assist the US Navy with tracking wildfires for firefighting purposes. The module uses electronics that help track important characteristics of fires such as humidity, temperature, and location. The device is made from 3D printed high impact and heat resistant material, and will be dropped via drone into fire active or prone areas. The design features five sub-assemblies with their own integrated electronics.

- Team Members: Jaime Isaiah Cervantes, Anthony Duyan, Blake Elliott, Noah Hinckley, Sonya Loredo, Andrew Mapes, Diana Mudeer, Philip Phan, Joseph Solis, Carson Vogel

- Team ARGUS lll Video

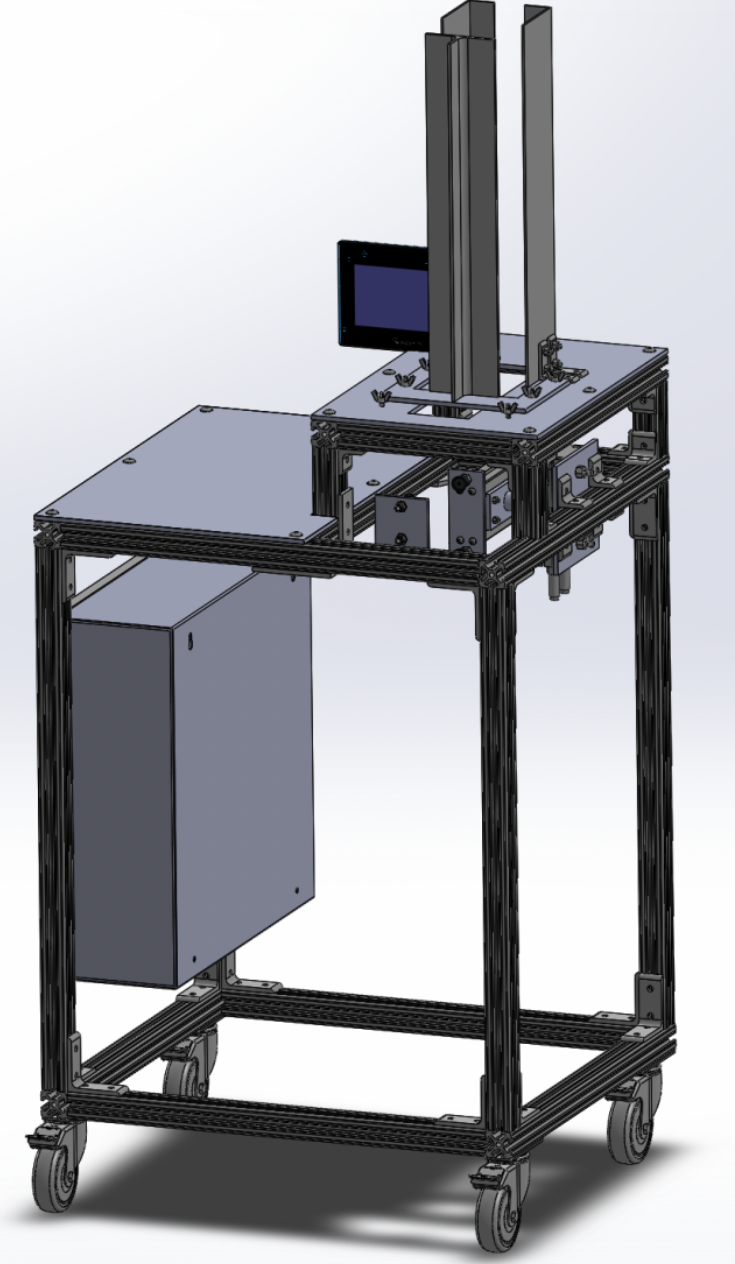

Team DiaBEATING Diabetes designed, developed, tested, and produced an automated verification test fixture for one of Dexcom’s newest, unreleased, products in their diabetes healthcare line. This automated fixture reduces time and cost of testing while simulating the conditions the device will experience in its lifetime. The test fixture puts the device through 100 cycles of testing and records and displays the number of test cycles performed while maintaining user safety and integrity of the device being tested.

- Team Members: Karen Lopez-Mendez, Lindsay MacLeod, Josemario Manansala, Erin Moore, Miguel Rodriguez

- Team Diabeating Diabetes Video

Masimo is a medical device company that manufactures 100 million medical devices each year and is in need of streamlining their current process of inserting adhesive sensors into pouches. To increase the production volume, speed, and accuracy, Team Bondi has designed an automated pouch opener/presenter for Masimo to implement into their facilities. The system uses a Programmable Logic Controller (PLC) and sensors to control the pneumatics in order to grab a pouch from a hopper and then opens and presents the pouch to an operator for sensor insert.

- Team Members: Zachary Conte, Jessica Grear, Hana Julazadeh, Jocelyn Arias, Chance Fugleseth, Thomas Trinh, Braden Hooper, Brayan Lopez Corona, Ryan Wilson, Abdulaziz Alali

- Team Bondi Video

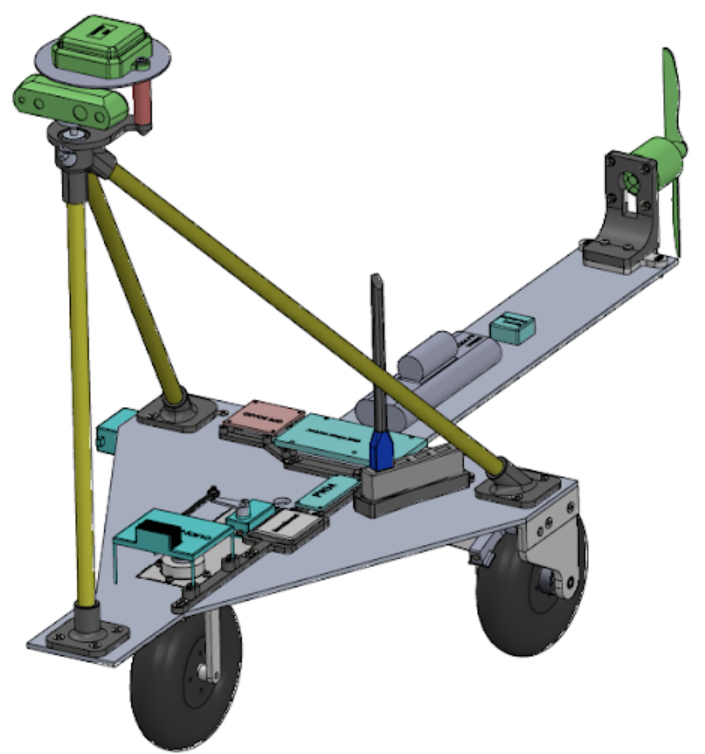

Team Maverick delivers a complex system for General Atomics's MQ-9A drone with their 1/10th scale drone with similar driving, steering, and brake systems utilizing the spiral design model that is capable of a high number of cycles, is low cost, easy to manufacture, and has high maneuverability. The drone incorporates GPS mapping through a UI to steer the drone to the target destination, taxiway line tracking, and object distance detection that brakes or slows depending on the distance detected of an object in view.

- Team Members: Paul Baker, Saja Allalao, Ezra Garcia, Alex Johnson, DJ Younkin, Sonny Pham, Andy Galvan, Gregor Krzyminski, Ofek Suchard, James Winter

- Team Maverick Video

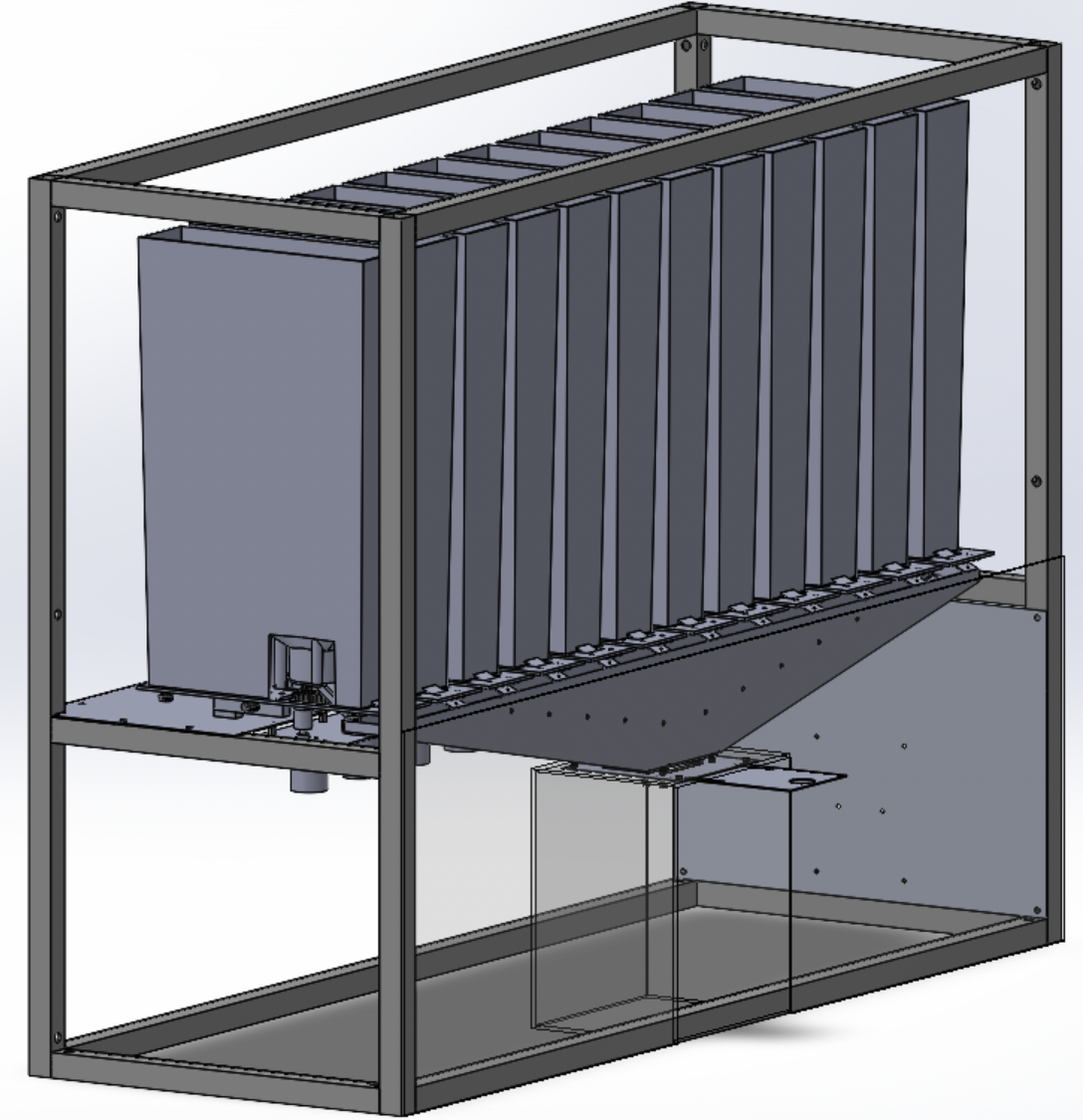

Team LUV Engineering has collaborated with Masimo engineers to design, document, and fabricate a system that emits UV-C light to all sides of various bagged and packaged medical objects for a known and controlled amount of time. Masimo uses UV-C light to disinfect finished medical products in a factory-line environment. This project aims to improve the UV-C disinfecting process that is currently used at Masimo by maximizing throughput and enhancing operational safety.

- Team Members: Micaela Rafael, Sara Herrera, Davis Owen, Calvin Phan, Matthew Hui, Brayan Rosas Vera, Tanner Askey, Nathaniel Guba, Lorance Malan, James Scobie, Lauren Prentiss

- Team LUV Engineering Video

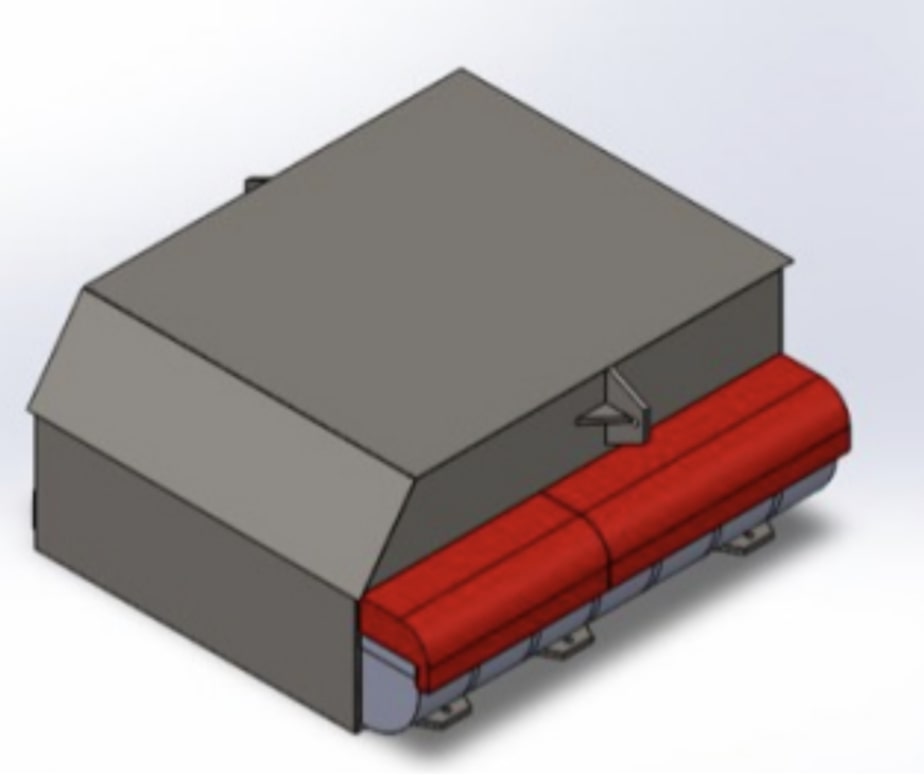

The Aztec Electric Racing team currently needs a battery box, or accumulator, which houses the battery cells and electrical components necessary for supplying the high voltage needs of an electric race car. It must have an efficient air-cooling system to keep the batteries and electrical components at the optimal operating temperature while running. Our team’s project is to design, test, and build an accumulator that will do so while staying within the regulations set by the Formula Society of Automotive Engineers.

- Team Members: Rukaiya Doctor, Ethan Gao, Samantha Harris, William Randall

- Team ChargeOne+ Video

The team is developing a new lightweight space robot that is multi-coordinated robotic system. The robot has the capabilities to be able to access and explore Mar's more challenging sites such as Hellas Planitia. The robot has the ability to exceed the force and payload capabilities to carry 5 times its own mass. It also has the inventive technology of soft robotics allowing for the retrieval of a myriad of samples.

- Team Members: David Aw, Christopher Choo, Abelardo Garcia, Cameron Jaynes, Sophie Koehler, Shingo Morita, Shahad Al Neesan, Andrew Richter, Martin Ruiz, Uriel Zamorano

- Team S.C.A.N Robotics Video

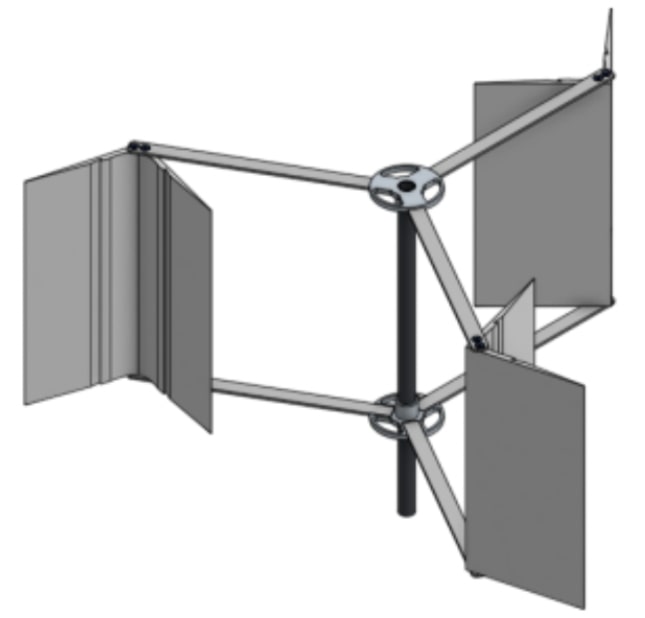

A Vertical Axis Wind Turbine (VAWT) has its axis of rotation perpendicular to the wind streamlines, i.e., vertical to the ground. Thus, it has a drag side which rotates against the wind, and the lift side which rotates in the direction of the wind. In this project, the team built a VAWT in such a way the flexibility of the blade reduces the drag on the upstream side while it increases the lift on the downstream side. The task of this project is to compare the efficiency of traditional rigid blades to new flexible blades for VAWTs.

- Team Members: Carson Campbell, Kellsie Dang, Isaiah Gentry, Angel Mora, Franco Ojeda

- Team Pacific Turbines Video

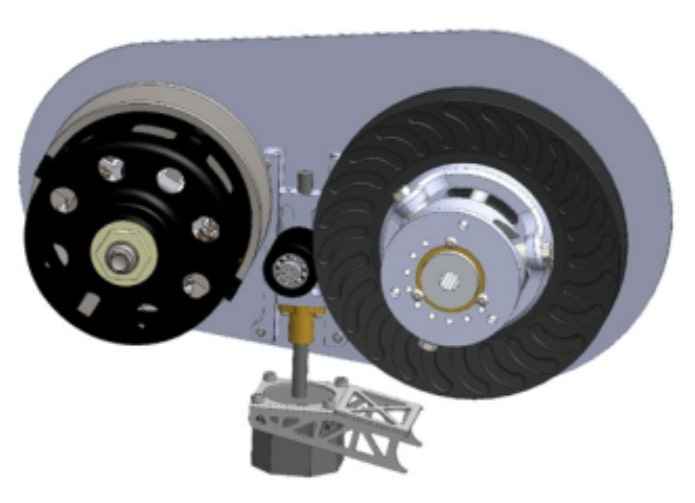

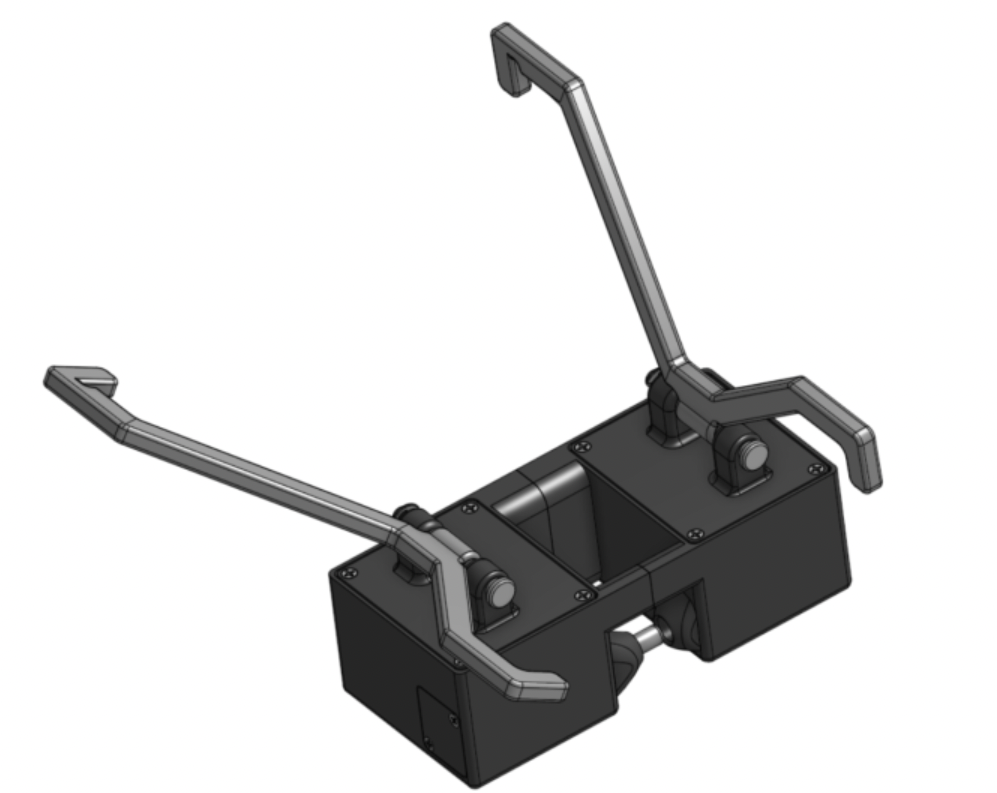

Aztec Baja’s SAE vehicle competes each year in the SAE Baja collegiate design series, where various aspects of the vehicle are tested. The car utilizes a continuously variable transmission (CVT), which is prone to shift issues in racing conditions. Team Electric Makos has designed and manufactured an electro-mechanical transmission assist component (EMTAC) to solve this problem. The EMTAC system influences shift

- Team Members: Kyle Bona, Stephen Drummy, Marcus Good, Andrew Ruff, Oskar Salminen

- Team Electric Makos Video

The team was tasked with designing, manufacturing, and testing a mechanical solution that would allow technicians inspecting Solar Turbines industrial gas turbine packages to depressurize the turbine’s equipment enclosure while the turbine is operating. The chosen solution is a leverage bar which a technician would use to open the enclosure door partially in positive and negative pressure differentials to allow pressure to equalize. The team then designed and manufactured a test rig for the device to collect data and verify the bar’s function.

- Team Members: Manuel Aldana, Kamron Arvand, Aidan Donaghe, Eddie Greer, Carlos Enrique Neyra

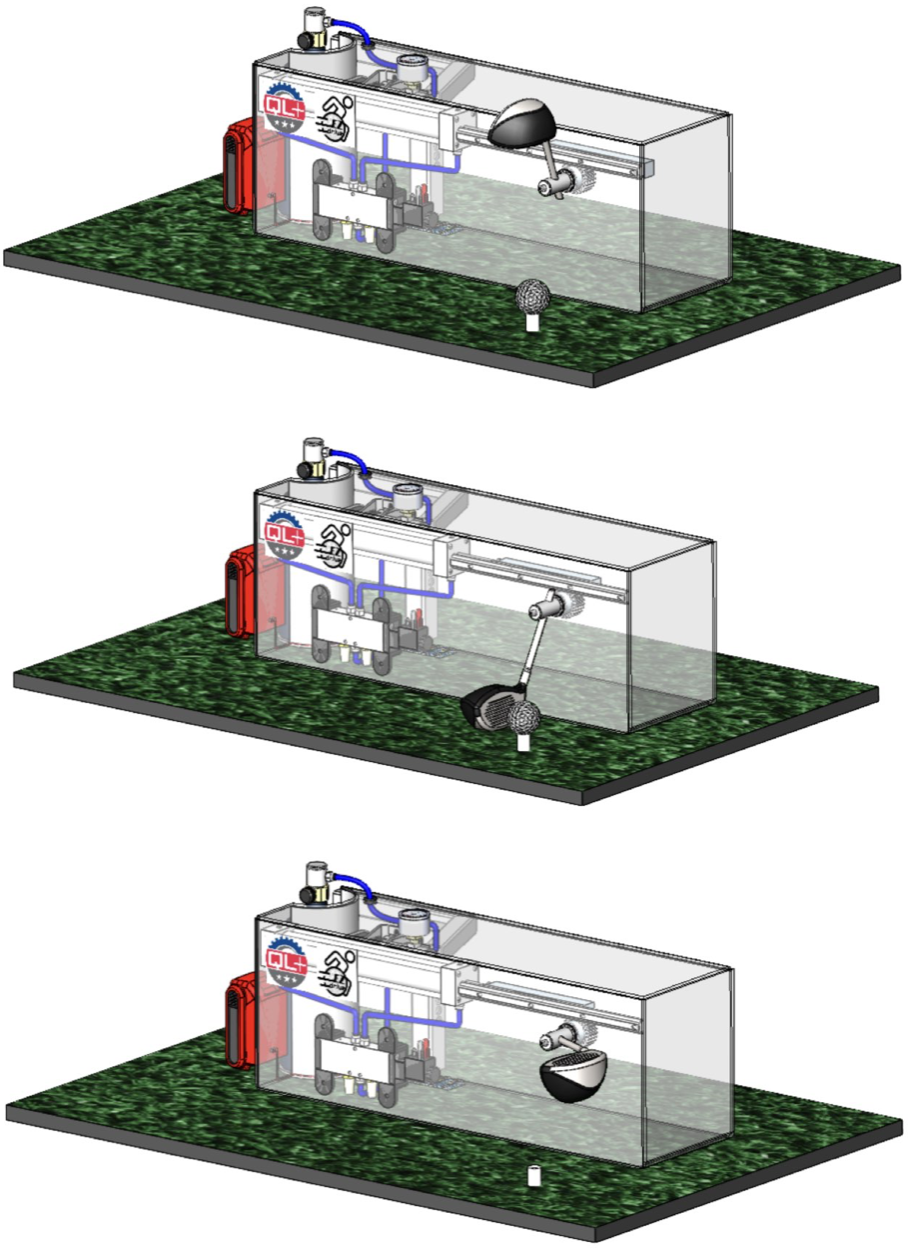

Our innovative device is specifically designed to enable disabled golfers to enjoy the game of golf, even if they cannot swing a golf club. Our goal is to overcome the limitations posed by physical disabilities through a sophisticated mechanical design. With just the press of a button, our device will be able to launch a golf ball down the fairway, using an accessible control mechanism such as a sip-and-puff system. This means that wheelchair-bound users with limited mobility can now participate in this great sport and experience the joy of hitting a golf ball.

- Team Members: Larry Arango, Dominic Bartlewski, Jerrick Claridad, Taiyo Gurule, Tanner Makar, Shakiba Abdul Sattar, Justin Cao, Briareus Castillo, Thomas Marshall, Tyler-Benjamin Puspos

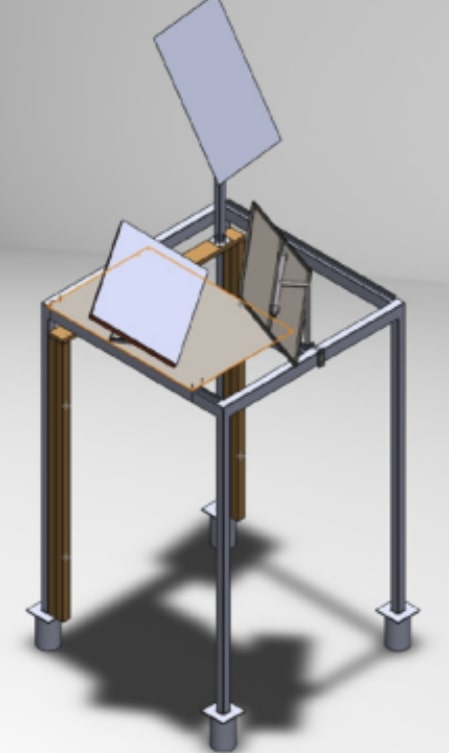

The goal of this project was to compare the performance of a GPS solar panel to a stationary panel with a reflector. This was achieved by creating a platform support system for the solar panels and reflector as well as designing the reflector to amplify the sunlight onto the stationary solar panel. The team manufactured a platform to raise the GPS solar tracking system above ground, which will allow the tracking system to position the panel perpendicular to the sun to obtain maximum sunlight and avoid shadows. Additionally, the team manufactured a reflector that can be manually adjusted to maximize energy collection. The successful completion of this project will provide important insights to solar energy research and help revolutionize solar energy production and implementation.

- Team Members: Patrick Anderson, Maganuco, Brenden Patch, Andrea Renteria, Christine Tan

- Team Sun Tilt Video

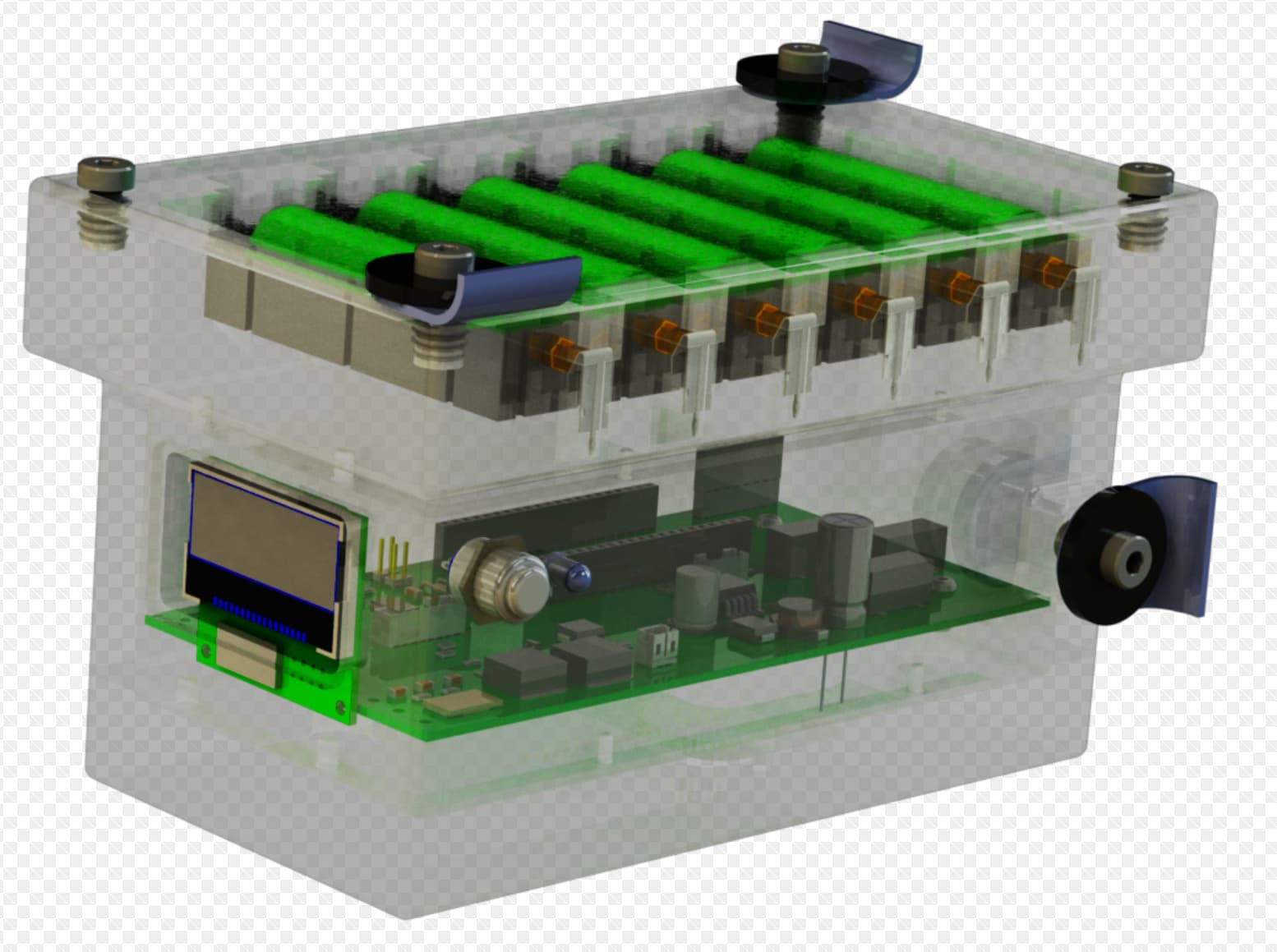

We have developed a compact, fire/water-proof Grounded Low Voltage Battery Power Supply for the SDSU Aztec Electric Racing Team to mount to their competition vehicle. It has a dual output power supply, powered by rechargeable batteries, with a battery management system to protect the electronics; an LCD screen to output live readouts of battery temperature, voltage, and current; and a pushbutton to light up an LED and initiate recording and storing of this data to be analyzed later..

- Team Members: Trevor Arellanez, Eugenio Casta, Jonas Schulson, Jack Topolesk, Evan Cuyler, Cyrus Yousefian, Pamela Gallardo, Joseph Fraticelli, Tyler Chu, Bader Alshammari

- Team Motorvators Video

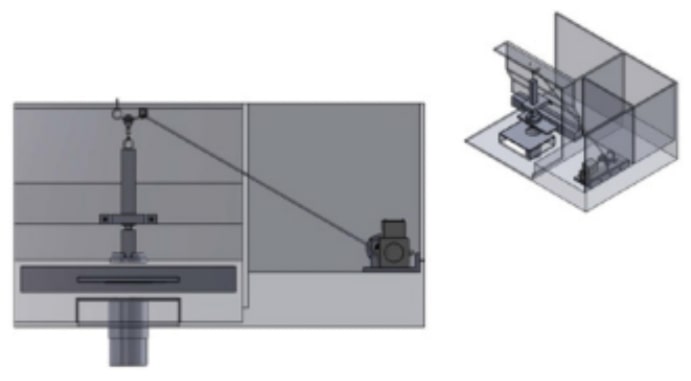

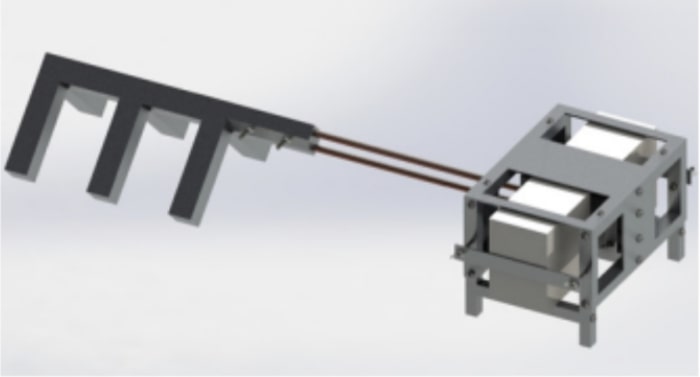

The Horn Antenna Fixture for Network Analyzer is a joint Mechanical, Electrical, and Computer Engineering team project to design, build, test, and document an automated test fixture for a network analyzer used to measure insertion and reflection loss of materials. The test fixture was designed for Laird R&F Products, who develops high-performance materials for the aerospace and defense markets and conducts insertion and reflection loss tests to determine the radio frequency properties of their products.

- Team Members: John Pateros, Conor O'Mahoney, Caleb Nieto, George Yousif, Livar Mikha, Peter Marrone, Cindy Rios, Christopher Rodriguez, Tyler Simmons, Christian Suatengco

- Team HAFNA Video

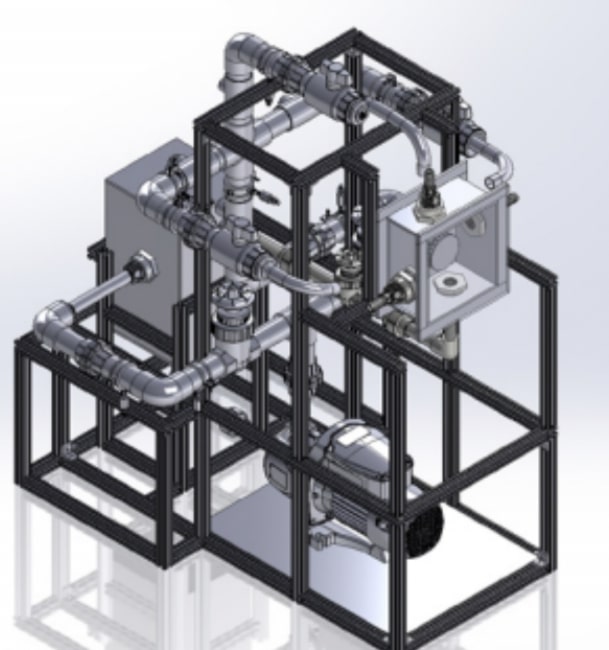

Fluidra is the largest manufacturer of pool and spa equipment. Fluidra’s current pool cleaning robot has a turbine and gear system to provide mechanical power to drive the wheels only. The team is tasked to add an electrical generator to the system to power low voltage devices. With water flowing at 4 gpm and 30 psi, the robot shall produce 20 W of power and no more than 30 V. To achieve this, the team has developed a testing apparatus to determine the most efficient way to convert fluid

flow into electricity.

- Team Members: Luis Aldrete, Joel Grieshaber, Kolton Nevins, Gaven Obrecht, Alan Reyes

- Team Under Pressure Video

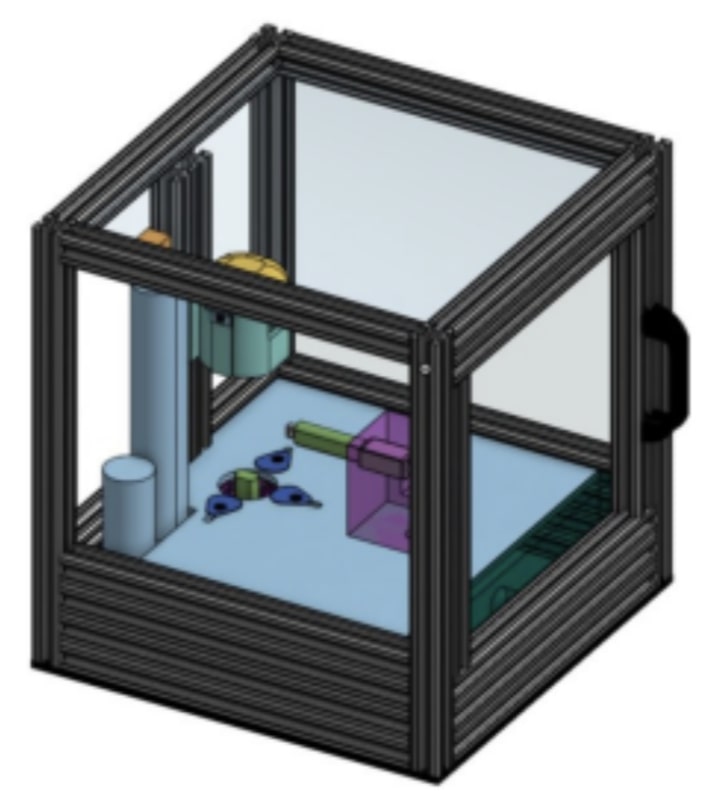

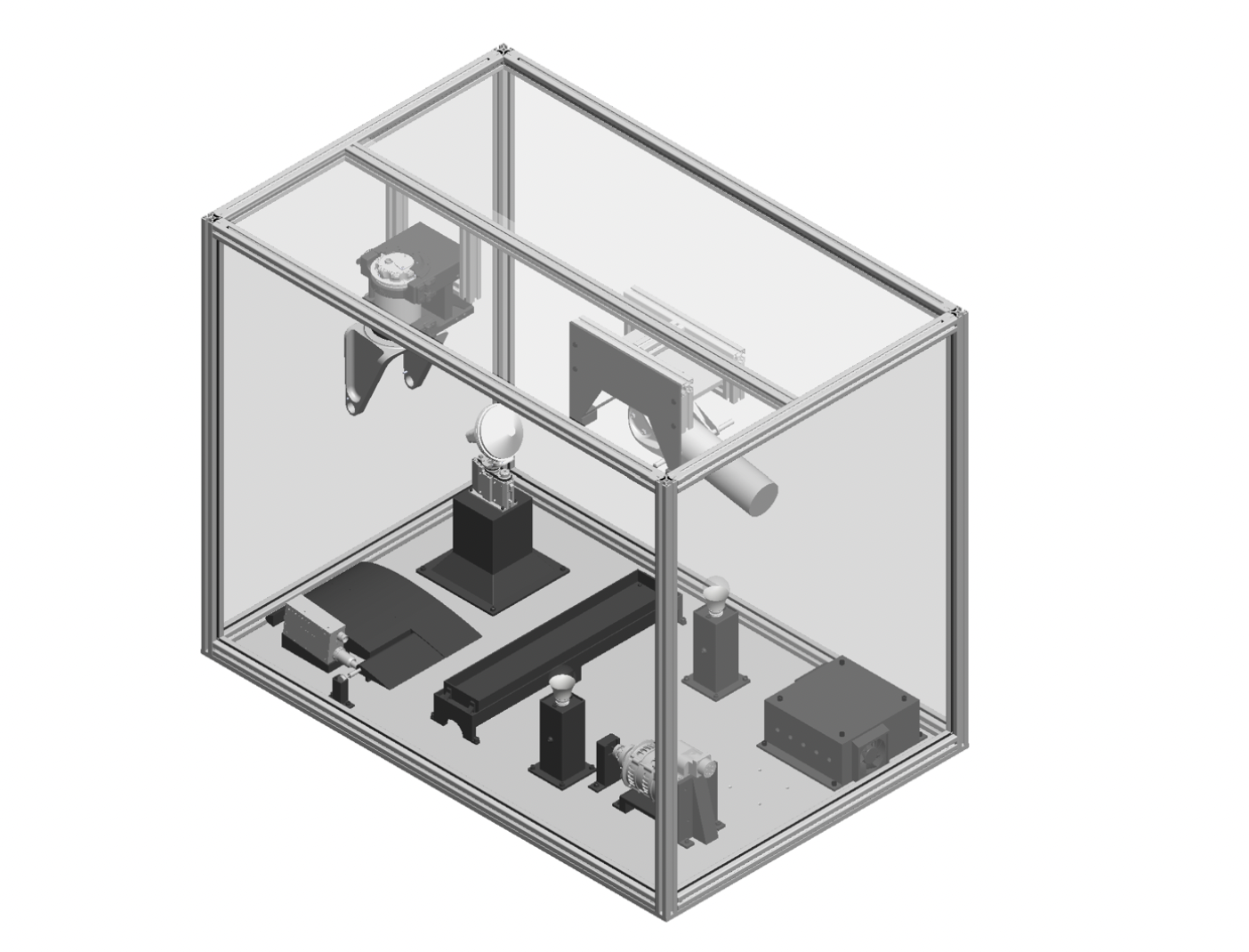

General Atomics Aeronautical Systems is one of the world leaders in the design and manufacture of Unmanned Aircraft Systems, radars, and electro-optic products. The goal of the Mechanical Assembly Display Automation is to manufacture a dynamic display, that will contain, and display the functions of components found within General Atomic-ASI's facilities and products. Users will be able to control the components located within the enclosure to view and understand how these parts operate.

- Team Members: Nathaniel Cordero - ME Jacob Cutter - ECE Chris D'orazio - ECE Sinan Kamil - ECE Lotanna Ene - ECE Alan Ta - ME Allen Ugalde - ME David Villareal - ME

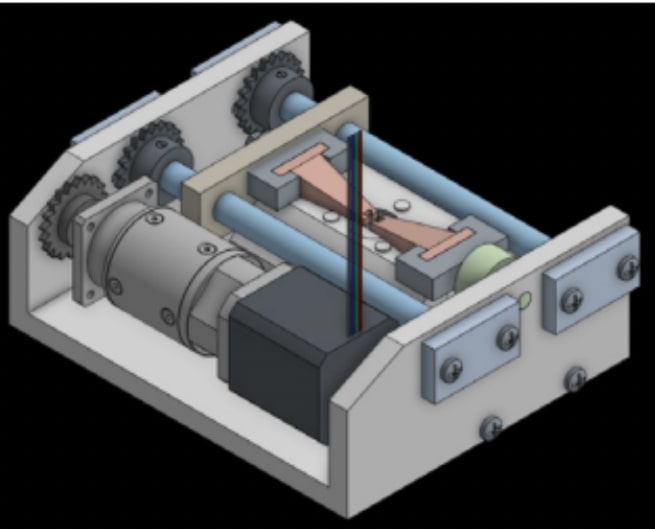

The project, sponsored by the SDSU Mechanical Engineering Department, is the development of a microstraining device that is to be coupled with a furnace that is part of the SDSU’s scanning electron microscope (SEM) equipment. The intended steel-made gripper device will apply tensile/compressive stress onto a very small (<4-6mm) metal sample under the hypothesis that polycrystalline microstructures, when heated it up, has an uneven redistribution of elastic energy between the grains and their boundaries.

- Team Members: Cindy Cabaluna, Willy Hua, Matthew Leslie, Thoran Meka, Tram Ngo

- Team Nexüs Video

ASML develops extreme ultraviolet, lithography light sources using laser-produced, plasma technology. A vacuum, test chamber used to develop new technologies such as heating and cooling elements, optimized gas mixtures, and new multilayer mirror (MLM) coatings can be problematic as temperatures reach up to 300°C during operation. In order to protect the samples, Team Mirror Mirror was tasked with the

design, build, and testing of a mirror holder capable of cooling samples below 80°C.

- Team Members: Hunter Atchley, Brenden Funke, Jorge Pineda, Andrew Preisler, Aaron Ramirez

- Team Mirror Mirror Video

This challenge is sponsored by NASA with the objective of finding new clean energy sources for future commercial aviation. The team researched, selected and anlyzed an alternative fuel for aviation that will reduce soot production along with pollutant emissions. The fuel selected is propane. To support this work, a propane combustion

chamber will be utilized to test soot output and carbon emissions in which the data will reflect the teams energy source chosen for NASA.

- Team Members: Steven Bach, Elijah Roa, Kyle Serbin, Larson Sevilla, Diego Tres

- Team Proplane Video

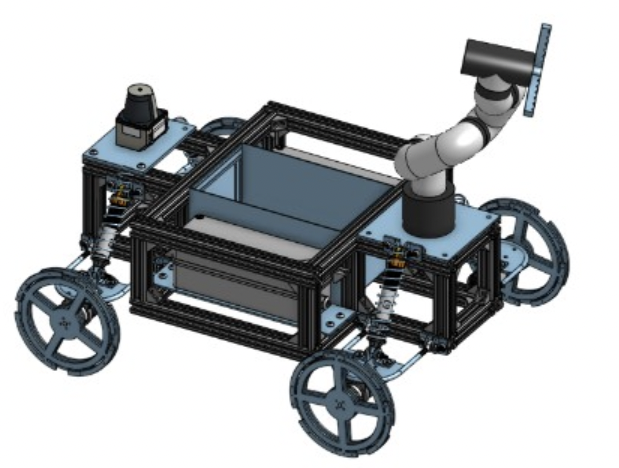

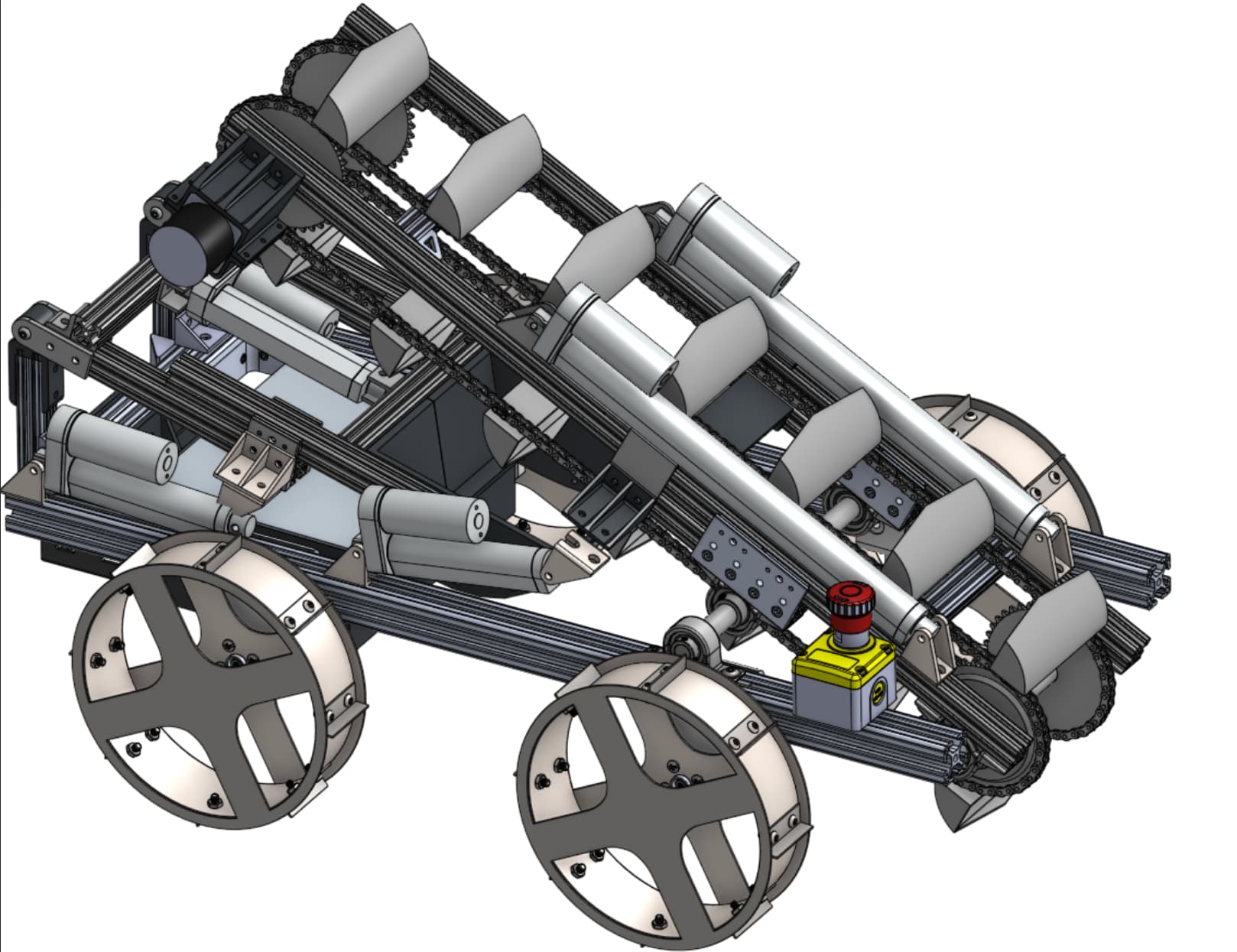

Team VULCAN is representing a joint Mechanical, Computer, and Electrical Engineering team from San Diego State University at the NASA Robotic Mining Competition Lunabotics 2023. The competition’s goal aims to prototype a rover capable of delivery to the moon in order to excavate lunar regolith beneath its surface, serving NASA’s Artemis Mission to the Moon. The rover will be capable of successfully completing a simulated mission of deployment to the moon to collect lunar regolith while avoiding obstacles and craters.

- Team Members: Leah Lafata, Angelina Parker, Ian Phelps, Dylan Lomas, Hunter Gavin, Jared Acosta, Joshua Putris, Juan Levya Carrillo, Kevin Breslin, Beqa Abulashvili

- Team Vulcan Video

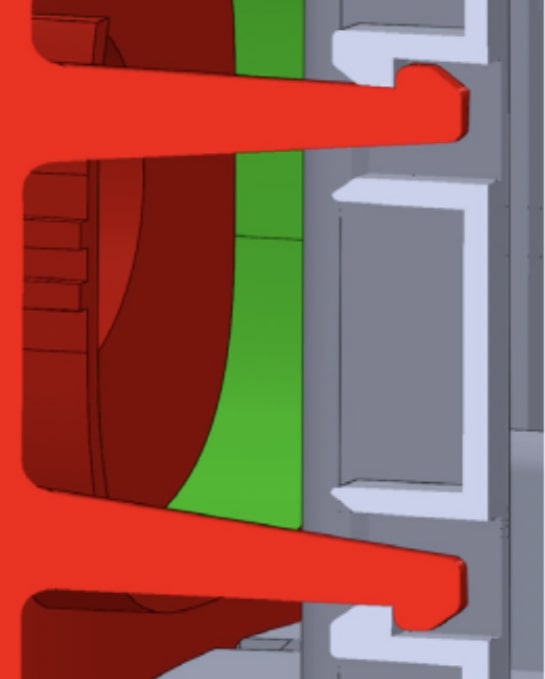

Dexcom is looking for an alternative to ultrasonic welding for the assembly of the components of their Continuous Glucose Monitoring System (CGM) applicator. In order to reduce assembly costs, increase reliability, and allow for high volume production of the applicator, Team Dextech has designed an alternative mechanical attachment method to ultrasonic welding. In this project, the team demonstrates feasibility of the replacement mechanism consisting of snap fits and press fits through analysis and testing.

- Team Members: Corey Jaquinod, Karla Navarrete, Briana Nieves, Clemence Rausa, Eric Tanori

- Team Dextech Video

Our team’s objective was to design and develop a removable pressure applicator system that could be installed internally into the largest binder jetting printer in the Powder Technology Laboratory at SDSU. The pressure applicator system includes removable weights to vary the pressure in between green body layers as a component is printed in order to achieve a decrease in the overall porosity of the final printed component.

- Team Members: Patrick Cruz, Brandon Nevares, Justin Palisoc, Khoa Tran, Francisco Zazueta Felix

- Team Sprinter Video

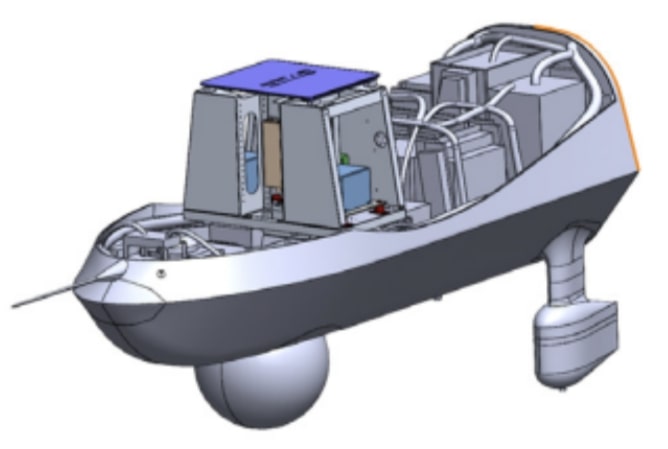

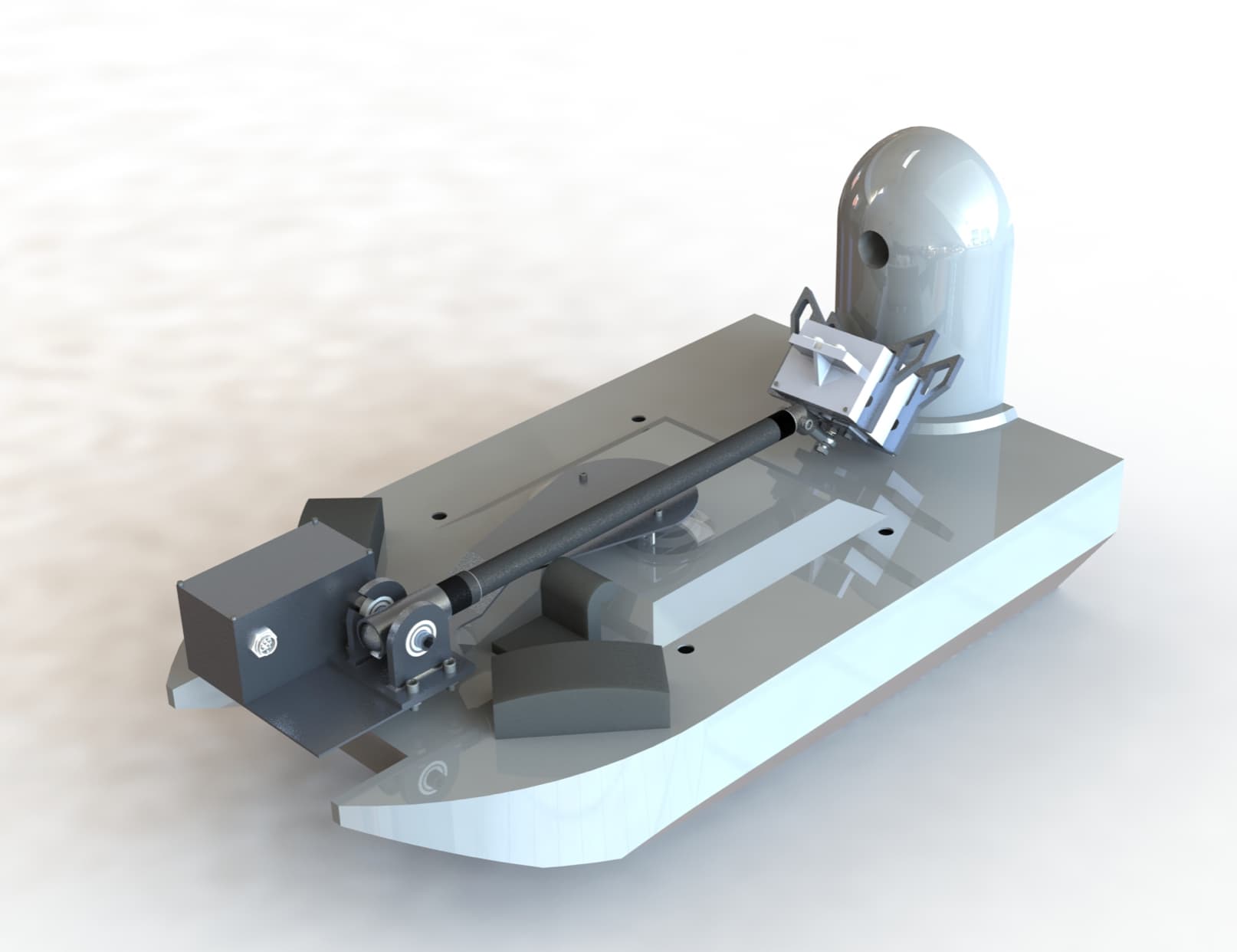

RES3RA is a deck-mounted attachment for Booz Allen Hamilton’s MANTAS (Man-Portable Tactical Autonomous System). The modular attachment will enhance the unmanned surface vessel’s ability to perform reconnaissance and surveillance missions. Currently, the delivery of surveillance payloads is performed by two operatives that jet ski to the target vessel and attach the payload to its hull with a long pole. The RES3RA aims to accomplish the same task in tandem with MANTAS, thus removing operatives from potential danger.

- Team Members: Nathan Reynolds, Andrew da Cunha, Nathan Whitford, Brian Herman, Trent McGill, Sammy Samaniego, Barry Baker, Milan Bujosevic, Oliver Shirley, Ackara Seav

- Team A.R.M.P.I.T. Video

This product will eliminate recycling issues by automatically crunching a can or bottle inside the unit to a significantly smaller size utilizing an internal gear a motor system. This unit will allow the user to place the product on the side of a bin used to collect recycling. Upon placing the standard 12 oz can or 16.9 oz water bottle into the cruncher, the unit will crunch the recycling without any further input from the user. aThis creates a hassle free method of recycling for all audience types.

- Team Members: Brendan Denney, Brady Lopez, Mateo Marquez, Zachary Morgan, Melissa Owens

- Team Recycruncher Video

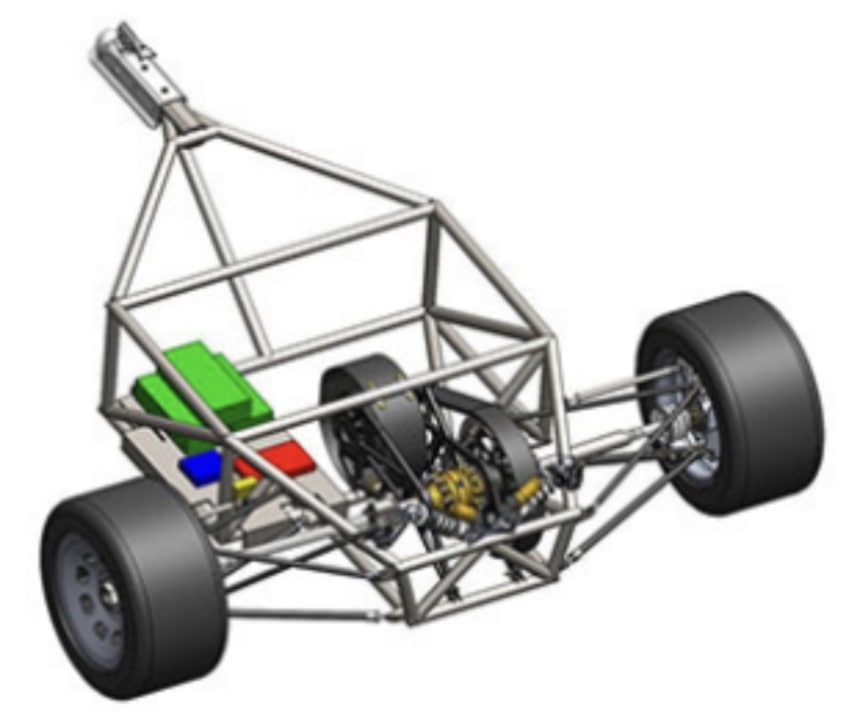

Every year, Aztec Electric Racing (AER) looks for ways to improve the performance of their Formula SAE Racecar. This year, the student-run club wanted to test a regenerative braking system to improve the car’s efficiency and range. The purpose of this project was to quantify the power sent back through the system at a variety of speeds under regenerative braking. The system was developed as a testing trailer

that attaches to the back of a vehicle and is a copy of the rear portion of the former 2022 AER racecar.

- Team Members: Ryder Bullock, Sonya Loredo, Christian Lunt, Jack Muller, Henri Stephan, Nolan Zaayer

- Team All Brakes No Gas Video

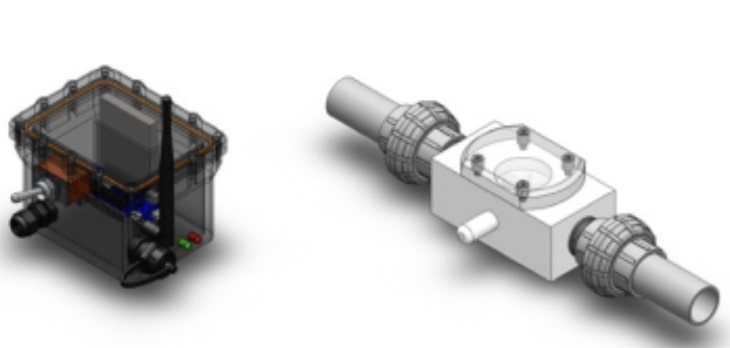

In residential irrigation systems, small, undetectable water leaks can cost a homeowner hundreds of extra dollars on their water bill. Team Poseidon Green Solutions was tasked to design a simple solution for detecting small water leaks at high risk locations. This device detects changes in the flow in the pipe and sends that data to the homeowner’s mobile device.

- Team Members: Aleksandr Abdurahmanov, Kaylista Halliday, Arghavan Sadeghi, Shon-Li Sutherland, Al Vincent Zabat

- Team Poseidon Green Solutions Video

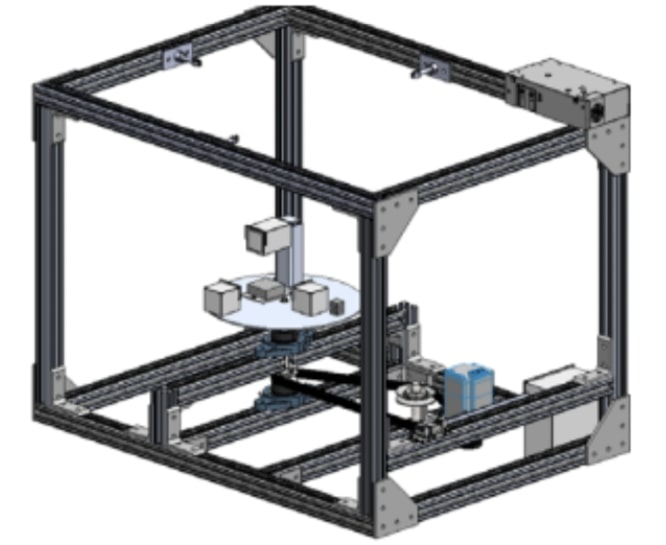

Current mechanical testing for materials used in impact mitigation neglects the effect of rotational acceleration, a common factor in concussions. The objective is to build a test apparatus capable of spinning elastomeric foam samples at variable speeds up to 3000 RPM based on the experimentalist command while capturing digital images

of the deformed surfaces. Ex-situ digital image correlation will be used to quantify the in-plane strain components, assessing the effects of rotational acceleration on the foam efficacy.

- Team Members: Nicholas Agtual, Madison Anderson, Dylan Lawrence, Kyle Mesch, Derek Nunotani

- Team Spin It To Win It Video

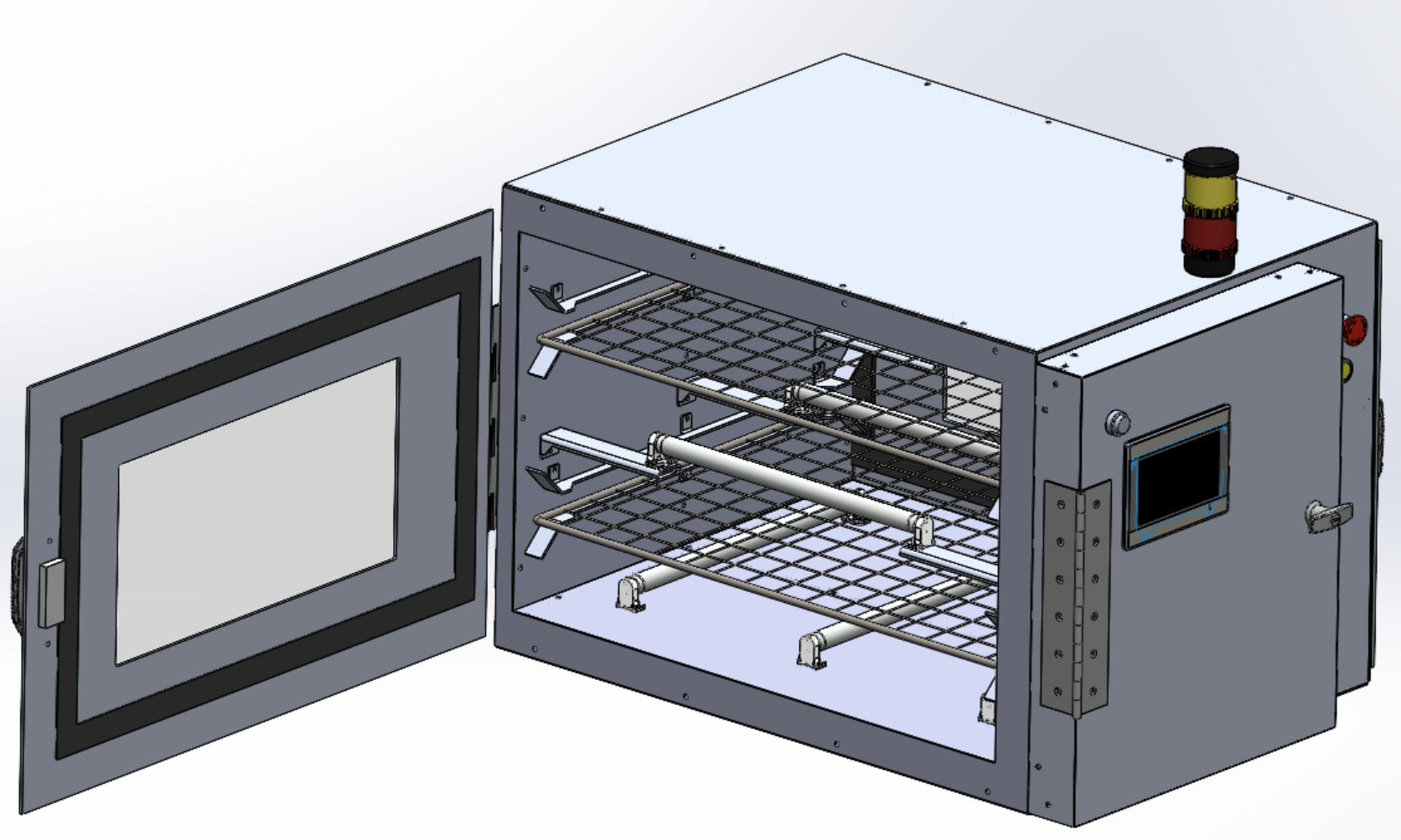

The Smart Cure Cabinet Monitoring System is an electrically integrated cabinet system to be used by Masimo’s production workers to register component information through a barcode system, assign the component a curing location and time, track its curing progress, and indicate the product's curing status to other production workers. Status will be shown by four timer modules attached to the cabinet, along with six others that can be attached to different curing station setups including open racks, cabinets, and ovens.

- Team Members: Olivia Orren, Oscar Campos, Samuel Kenny, Kendra-Rose Jucal, Matthew Fontimayor, James McGill, Cody Nephew, Eddie Donovan, Abdullah Bin Essa, Luka Kurashvili

- Team Autoclox Video

D&K Engineering has enlisted the help of SDSU students in designing a Smart Granola Kiosk capable of accepting user input for payment and ingredient selection. Customers will use an app to place orders via a tablet on the kiosk or through a smartphone via a mobile app. Once an order is placed, the granola then dispenses to the customer via a food safe delivery system. The kiosk will be modular and food safe according to FDA regulations.

- Team Members: Dylan Mazzarella, Jarlen Nicholos, Joshua Alanzalon, Nathan Dockswell, Jian Cai, Rylan Bumbasi, Joseph Placido, Lauren Halbach, Manuel Medina, Rodrigo Sosa

- Team Granola to Go

Team Hephaestus was tasked by SDSU Mechanical Engineering Department’s Chair, Dr. Abraham, to create a sustainable power generator through the use of Thermoelectric Devices. The team has crafted a product that will use the high temperatures of a traditional campfire to distribute the heat into two Thermoelectric Modules through a heat exchanger. The TEMs will be used alongside two Cooling Units to produce a suitable temperature difference to charge a 14.8 V battery, which can charge a slew of electronic devices.

- Team Members: Andres Cardenas, Dalaney Conte, Bryce Horton, Mathew Tivey, Caroline Yu

- Team Hephaestus Video

Team Soteria designed and manufactured a payload deployment for search and rescue teams. The goal of the payload is to be able to carry lightweight emergency supplies to remote locations with the use of the current Search and Rescue (SAR) drone, the DJI Mavic 2 Enterprise. The payload is lightweight, portable, and non-intrusive to the drone sensors. The attachment method is interchangeable, and the release mechanism is initiated through audio signals and can be done from any distance the drone can fly.

- Team Members: Adam Campbell, Alex Aguilar, Bryan Kennedy, Danny Tisnado, Dylan Vann, Liam McCue, Mason Stark, Nabi Habib, Riley Livers, Sam Halabo

- Team Soteria Video

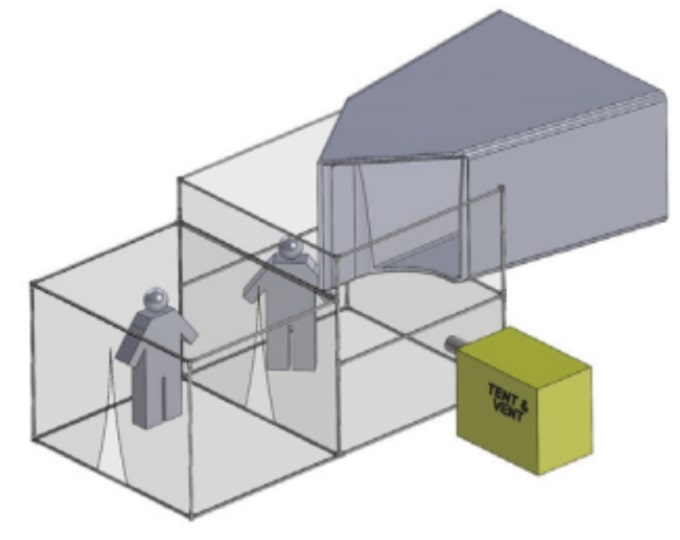

This project provides the Ellsworth USAF with a portable/reusable bioengineering compliant finishing structure used for the nacelles of the B-1B aircraft. This ready-to-use product solution eliminates a major safety hazard to the USAF team. Key features of the finishing structure include; collapsibility, height variability and a separate enclosed decontamination room. The PVC structure is easy to procure, cost effective and architecturally adaptive for other aircraft.

- Team Members: Eric Apgar, Travus Clark, Hernan Velazquez Munoz, Daniel Murillo, Joshua Pasco

- Team Spray ‘n Prey Video

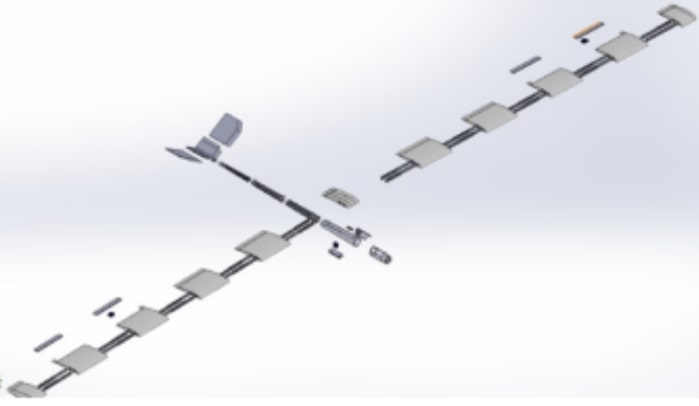

The Hot End Aeronautics team has designed and manufactured a 3D printed fixed-wing aircraft with the goal of prolonged flight to compete in the 3D Printed Aircraft Competition (3DPAC) hosted by California State University, Los Angeles. The project guidelines call for an aircraft that can glide the longest with a safe propulsion method for 8 seconds. All components must be 3D printed other than the electronics within the aircraft. The aircraft shall be designed as a glider in order to perform competitively.

- Team Members: Alexandre Balensi, Alexander Brown, Josh Gipson, Henos Hussien, Matt Owens

- Team Hot End Aeronautics Video

This team performed research, analysis, and testing to design and manufacture a fully 3D printed RC aircraft with the purpose of winning both the Most Innovative Design and Longest Duration of Flight awards in the fixed-wing category at the 3D Printed Aircraft Competition to be held in May at Cal State Los Angeles. All lifting surfaces and aircraft components must be 3D printed, except for electronics, the propeller, and some hardware. The aircraft is allowed to be powered for only 8 secs and must fly under a 30 ft altitude.

- Team Members: Drake Campo, Oscar Correa, Xavier Major, Ben Saldana, Kenton Williams

- Team Plane and (not so) Video