Fall 2024 Design Day

Our Fall 2024 Engineering Design Day event will be held on Tuesday, December 10th, 2024, from 1:00pm-3:30pm in the EIS Courtyard.

Design Day is the largest College of Engineering event and it showcases the exciting and innovative design projects that our undergraduate Engineering students conceive, design and build during the academic year. Each Senior Design classes in Aerospace Engineering, Civil, Construction & Environmental Engineering, Electrical & Computer Engineering, and Mechanical Engineering will be participating. 16 projects will be showcased at the 2024 Engineering Design Day event. Below are the Mechanical Engineering Senior Design projects that will be showcased at the event (More details of individual projects will be available as the event draws closer).

Design Day Projects

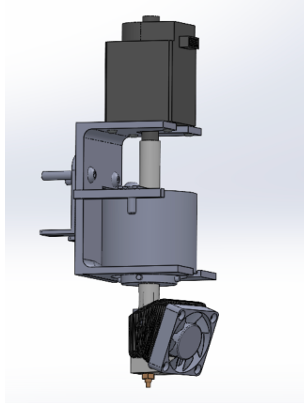

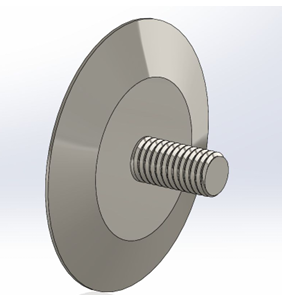

The goal of this research was to create an improved and stronger 3D printing structure than current commercial 3D printers in the market. The project objectives were to analyze the components of a Fused Deposition Modeling (FDM) 3D printer, design and produce a nozzle that mimics the extrusion of a spider web, and study the mechanical behaviors of 3D printed structures produced by the new nozzle. The materials used and tested for this research were silk PLA (polylactic acid) and Carbon Fiber PLA filament

- Team Members: Marc Fuentes, Tasia Gary, Joseph Romero

Thermal blankets provide thermal, acoustic, and fluid protection to the nacelle structure from its engines. Collins Aerospace is interested in the development of a lighter, cheaper, and more effective thermal blanket than current production blankets. Students were tasked to further investigate the previous cycle’s findings to refine the design and feasibility of integrating aerogel into the blankets.

- Team Members: Vedat Anwar, Luis Cardoza, Oliver Fernandez, William Harper, Ethan Morrison

Utilize custom 3D printed curved surfaces that accommodates complex seal geometry. Apply controlled compression load onto seal with linear actuators and measure force and deformation data via three load cells and potentiometers. Using the data gathered, the experimental seal stiffness can be calculated. After the experimental stiffness is determined, an ANSYS model was created and correlated against the data. The ANSYS model was solved in various ways including an ACP model with fiber layers and solving it as a solid body in order to determine which FEA method yielded the best correlation to the experimental data to provide an accurate model.

- Team Members: Nick Anderson, Mathew Simon, Josh Chau and Connor Carrasquilla

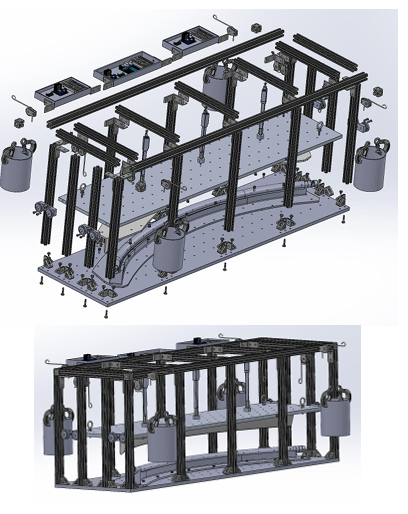

As a team we designed and built a larger scale automated composting system. It has an automated mixing mechanism that turns the compost for aeration based on either time and/or temperature of the compost, and measures and monitors temperature and moisture content for optimal composting.

- Team Members: Elena Binns, Kathia Brown, Andres De Casas, Steven Evans

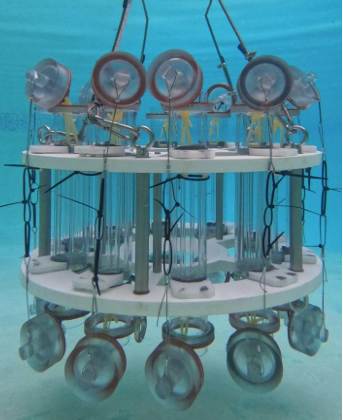

Carbon dioxide sequestration is the practice of capturing, securing, and storing carbon dioxide emissions from the atmosphere. This is done by sinking marine algae into the deep ocean where it remineralizes itself into the atmosphere through the short carbon cycle. The short carbon cycle is the process of cycling carbon dioxide from the earth to the atmosphere, typically through decomposition of plants and other organisms, a process that takes between 100-200 million years to complete. The long carbon cycle offers a manner of transferring carbon dioxide through the crust of the earth which is more beneficial towards repairing the damages from fossil fuels.

- Team Members: Grant Eggers, Gavril Buenaventura, Barbara Alvarez

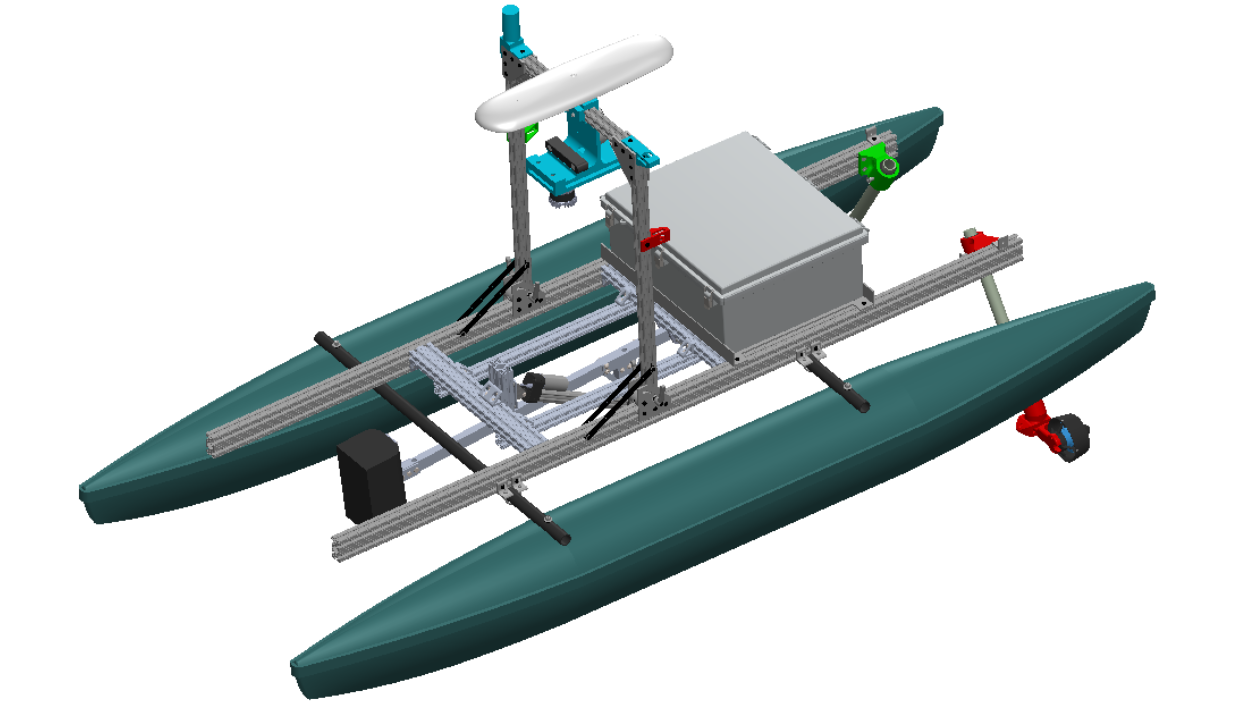

The team worked the Naval Information Warfare Center (NIWC) to develop a mount and machine learning vision algorithm for a sonar sensor to be integrated to their Green Uncrewed Surface Vessel (GUS-V). The project included several systems including a custom PCB for sonar and linear actuator control, custom machined and water cut parts, and extensive software development to integrate the sonar with existing GUS-V systems. The machine learning algorithm utilizes the open source You Only Look Once (YOLO V9) algorithm which was trained using over 10,000 images of underwater objects. The algorithm can identify simple shapes underwater and relays that information in real time to a shore side computer.

- Team Members: Tommy kenton, Ethan McCaffrey, Joesph Morales, Emilee Smith

- DeepVision Sonar Mount Video

Our design features a mechanical and pneumaticallydriven underwater vessel that harnesses falling water's potential energy to generate power. The system incorporates three distinct piston types along with two dual mirrored bait and tackle pulley systems. Our objectiveis to develop an underwater energy generation device that could harness the potential energy of falling water.

- Team Members: Owen Flynn, William Lingle-Veale, Esteban Gomez, Tristain Lachman, Christopher Bales

SLA 3D printing relies on IPA for cleaning, but waste resin quickly saturates it, increasing costs and waste. Our project addresses this by designing an IPA recycling system for the Form Wash L, combining UV light and filtration to maintain IPA saturation below 10% for three months, reducing waste and downtime.

- Team Members: Guillermo Fragoso, Alexander Messick, Christian Phoebus and Noah Rouimi

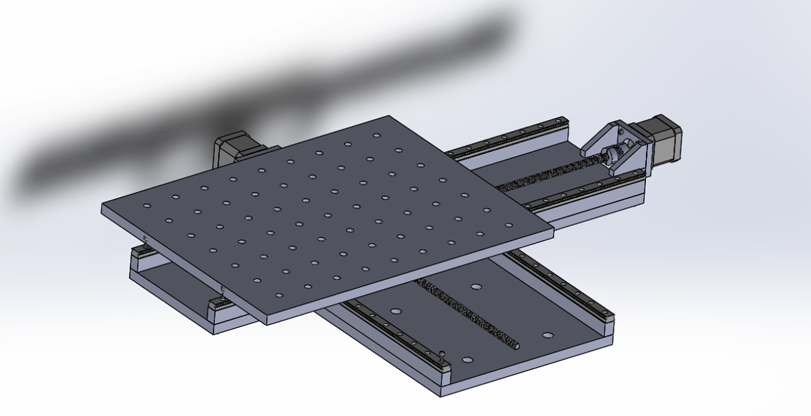

The SDSU Mechatronics team often needs to drill precisely located bolt patterns, but they only sometimes have access to the machine shop to use the tools there. This is time consuming since there is a wait time for access to the machine shop and because it is away from the main trailer. To speed up their manufacturing process, our project is to design a custom CNC cross table to help position components under their drill press. The main challenge in the making of this project is the precision that is needed but the low budget. With a budget of about $300 we need to give a precision of 0.010 true position tolerance during drilling operations.

- Team Members: Jack Sichantha, Khanitha Soeung, Ariel Karich, Jan Andrew Aviles, and Gerardo Pineda

This project aimed to automate the inspection process for a biomedical company, reducing human intervention and improving time efficiency in production. The goal was approached by using the Dobot Magician robotic arm, programmed for precise and repeatable part handling. The robot operates on a strategically designed table layout that prioritizes error prevention and ensures optimal functionality.

- Team Members: Donovan Orozco, Jose Silva, Thomas McCluskey, Franklin Landeros, and Oliver Casillas

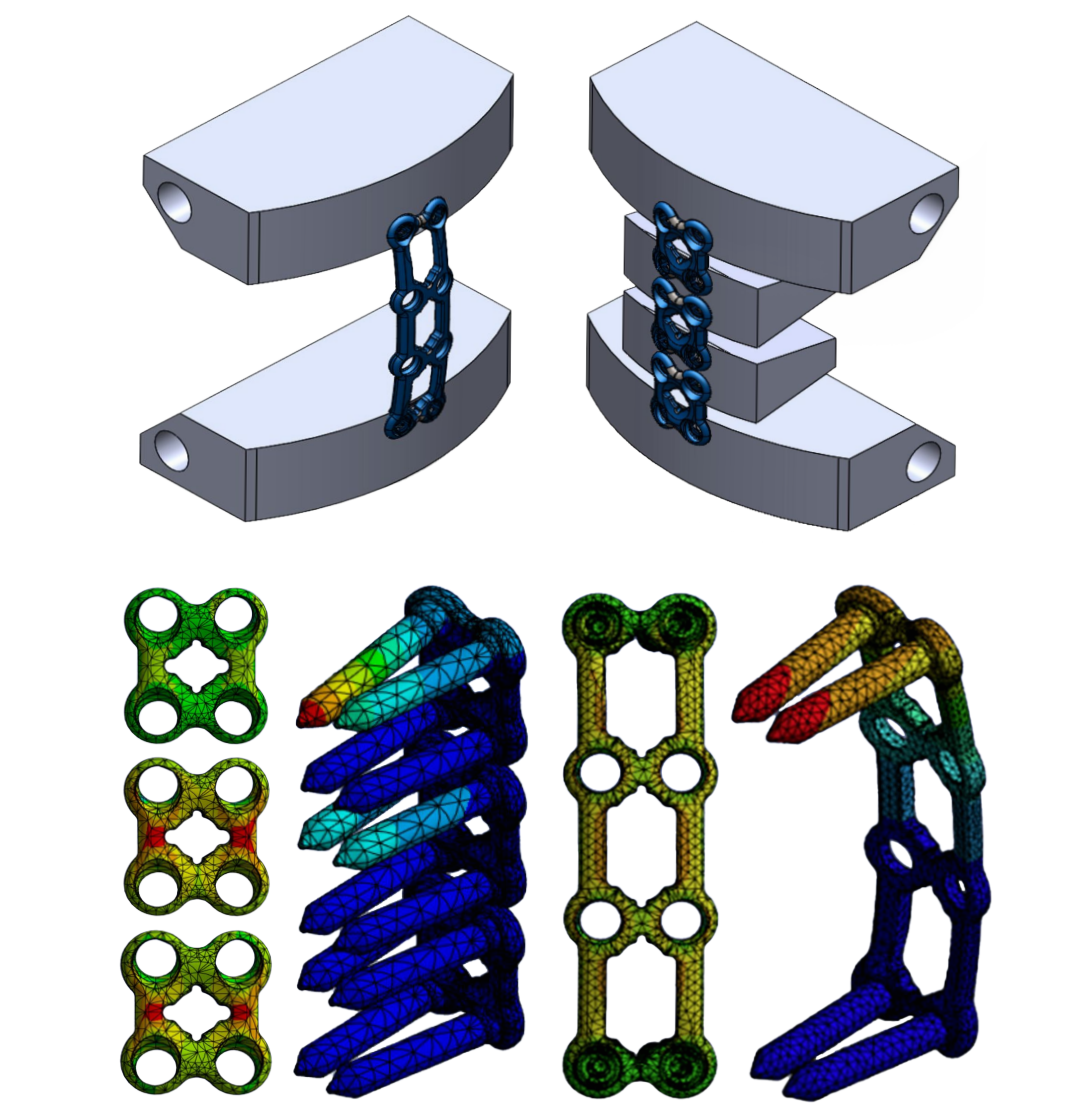

This project investigates the mechanical performance of anterior cervical plates used in ACDF procedures to address spinal instability caused by conditions like Degenerative Disc Disease. The team designed custom fixtures and conducted Finite Element Analysis (FEA) and mechanical testing to compare stacked segmental and multi-level plating systems under static compression and torsion. Results showed stacked plates improved stress distribution, while multi-level plates exhibited higher stress concentrations. This research provides valuable insights into spinal implant performance, contributing to advancements in cervical spine treatments.

- Team Members: Daralyn Johnson, Jack Kuffner, Joseph Cruz-Santillan, Arieal Swindell

Our project was a 4-point lift system designed to limit rotation, tilting, and lift up to 250 lb. Its purpose was to make the shop more efficient by enabling a single individual to easily lift truck accessories, such as ladder racks, and install them, while still following Osha and local codes. Our final design features a central shaft driven by a hoist motor and supported by a bearing. Four cables are attached to the shaft, routed through pulleys, and connected to a base frame with straps and carabiners for easy lifting and installation.

- Team Members: Connor Penn, Seth Rodriguez, Josiah Hull, Wyatt Havin, and myself Nick Taboga

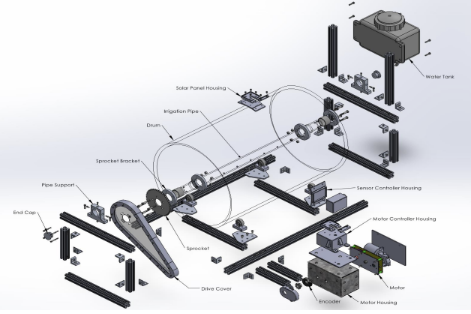

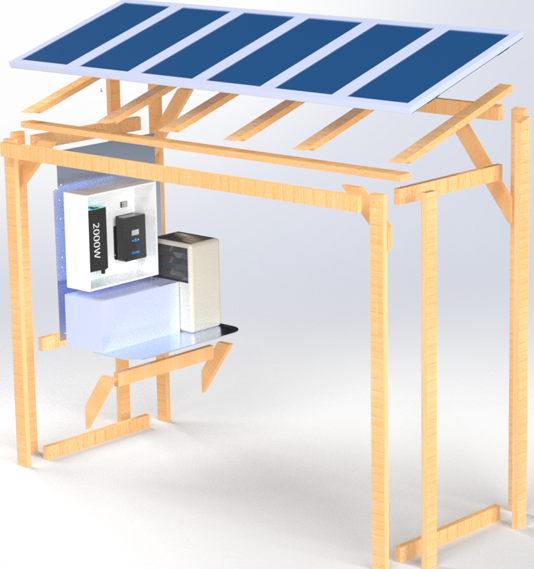

Verify, design, and develop an atmospheric water generation system that pulls usable, clean water from ambient air using solar panels. By obtaining clean, demineralized water from a virtually limitless source as the atmosphere, we can ensure that the carnivorous plants being cultivated at SDSU's greenhouse will always have a freshwater source.

- Team Members: Tantra Ly, Fox Bonner, Joseph Shelby, Jesus Hernandez, and Jan Caesar Castaneda

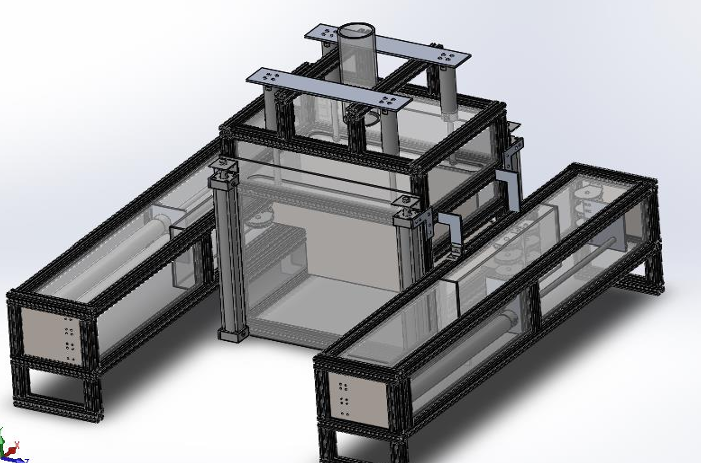

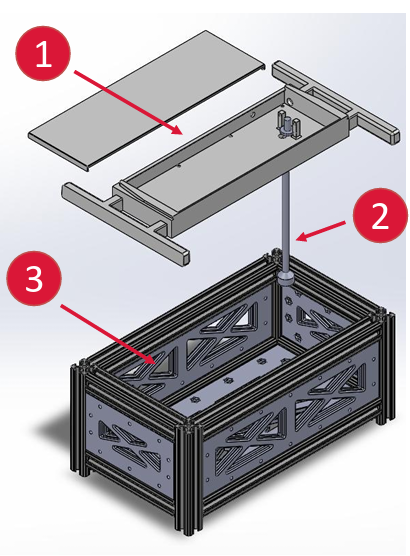

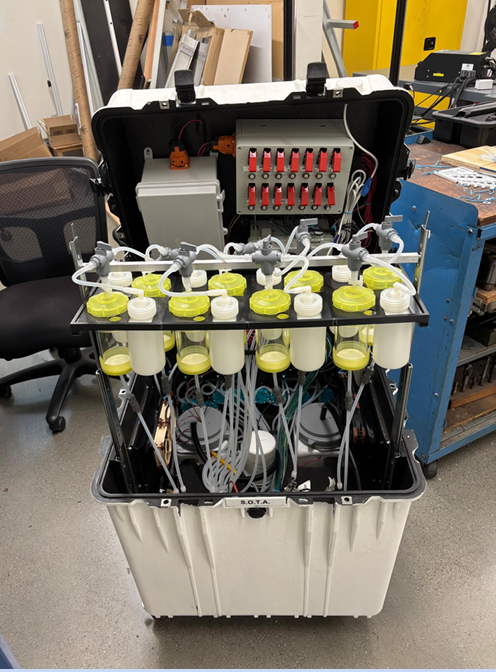

The Naval Information Warfare Systems Command is developing a testing apparatus as part of the NESDI program for the purpose of identifying Per- and polyfluoroalkyl substances PFAS, primarily for possibly contaminated water supplies found in naval facilities and ships. PFAS is a synthetic chemical which has been linked to an increased risk in cancer amongst those exposed, and has become an increasingly problematic issue that requires action. A compact system which incorporates hydraulics, electronics, and additive-manufactured components has been developed with remote-access and solar-power capabilities to provide reliable testing data regarding the concentration of PFAS materials in a given water source. The developed apparatus is not only durable, but is wholly contained within a portable and relatively lightweight mobile case Not including the external solar panels and power bank).

- Team Members: Trey Lundberg, Chase White, Kelvin Huang, and Amory Quinn

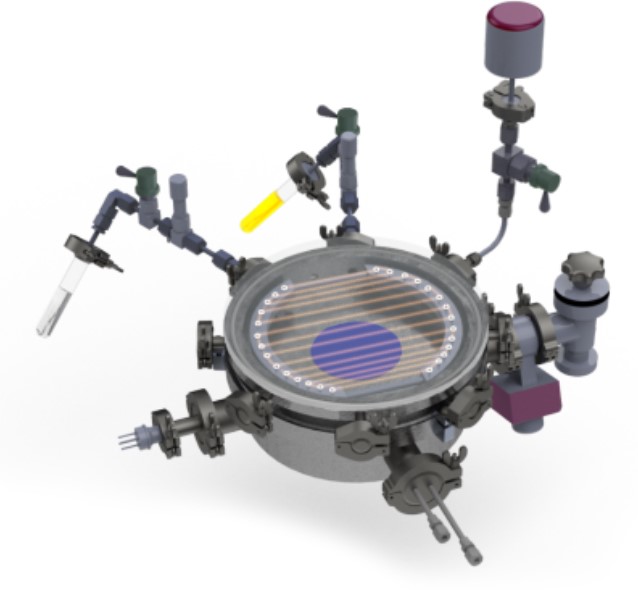

Chemical Vapor Deposition(CVD) is the process of evaporating monomers using high temperatures while inside a vacuum chamber to coat the surface of a targeted object. Our Team was tasked with locating and fixing leaks within this iCVD reactor chamber to achieve low pressures (10 mTorr) and a minimal leak rate (10 mTorr/min). This chamber was attached to a 220V Vacuum pump to evacuate the air inside, and a pressure gauge to measure the internal pressures. Our testing was able to prove the chamber can achieve low pressures and is leak free and now can be used for experimenting in AMED lab.

- Team Members: Isaiah Hansink, Rajiv Mangukia, Ignacio Carrillo, Jesse Gomez, Ahn Tran

This project focused on developing a 3D-printed artificial coral reef habitat to combat coral reef degradation caused by microbialization, overfishing, pollution, and climate change. The team designed and fabricated a durable floating structure made of Polylactic Acid (PLA), engineered to withstand oceanic forces while providing a geometry conducive to marine life and resistant to microbialization.

- Team Members: Clement Luu, Mason Cook, Andre Abaya, Jonathan Bautista, Nicholas Entrup