Fall 2025 Design Day

Our Fall 2025 Engineering Design Day event will be held on Thursday, December 11th, 2025, from 1:00pm-3::30pm in the EIS Courtyard. Learn more about where to park here.

Design Day is the largest College of Engineering event and it showcases the exciting and innovative design projects that our undergraduate Engineering students conceive, design and build during the academic year. Each Senior Design classes in Aerospace Engineering, Civil, Construction & Environmental Engineering, Electrical & Computer Engineering, and Mechanical Engineering will be participating. 12 projects will be showcased at the 2025 Engineering Design Day event. Below are the Mechanical Engineering Senior Design projects that will be showcased at the event (More details of individual projects will be available as the event draws closer).

Design Day Projects

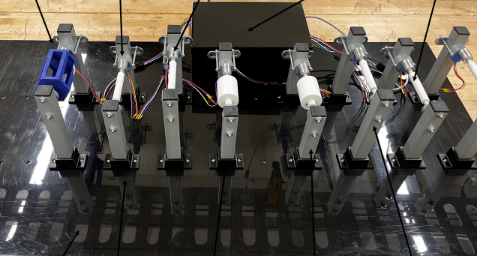

This project focuses on developing a custom powder-layering printer architecture designed to support Electrically Printable Additive Manufacturing (EPAM) in future work. The goal was to engineer a system capable of executing the mechanical

sequence required for EPAM: controlled powder deposition, uniform layer preparation, precision motion, and software synchronization. The resulting platform integrates a hopper, recoater, roller, and electrode positioning system within a

custom firmware and G-code pipeline that enables timed, step-by-step operations compatible with future pulse-based metal printing processes.

- Team Members: Preston Ea, Takehiro Masubuchi, Mathew Peterson, Jesus Contreras, Chirstian Jones

- Team Members: Jacob Cahill, Josef Wiest, Jacob Baumgardner, Noah Davis, Alvin Gopez

procedures and conditions to measuring and validate the wear on surgical drivers

over multiple cycles. The results will help determine the operational lifetime of

Carlsmed drivers used in surgeries.The testing system operates by using a reprogrammed 3D printer to drive the motor-powered screwdriver which inserts

a titanium screw into bone foam material. The torque sensor positioned beneath the

bone foam plate records the output torque. Additionally, a load cell measures the axial force applied as the driver presses into the screw.

- Team Members: Mohamed Alagha, Nicolas Martinez-Medina, Ansh Lall, Helen Trinh, Tono Yahuaca

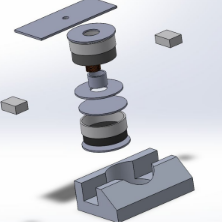

In Phase I, the ANSYS FEA model for nacelle seal stiffness was incomplete, leading to discrepancies with mechanical test data. Without an accurate model, reliable stiffness prediction was not possible. Phase II addresses this by generating an accurate, validated FEA model using material properties derived from the improved mechanical compression test rig.

- Team Members: Roy Foley, Kaylee Tirado, William Sotelo, Kevin .Lopez

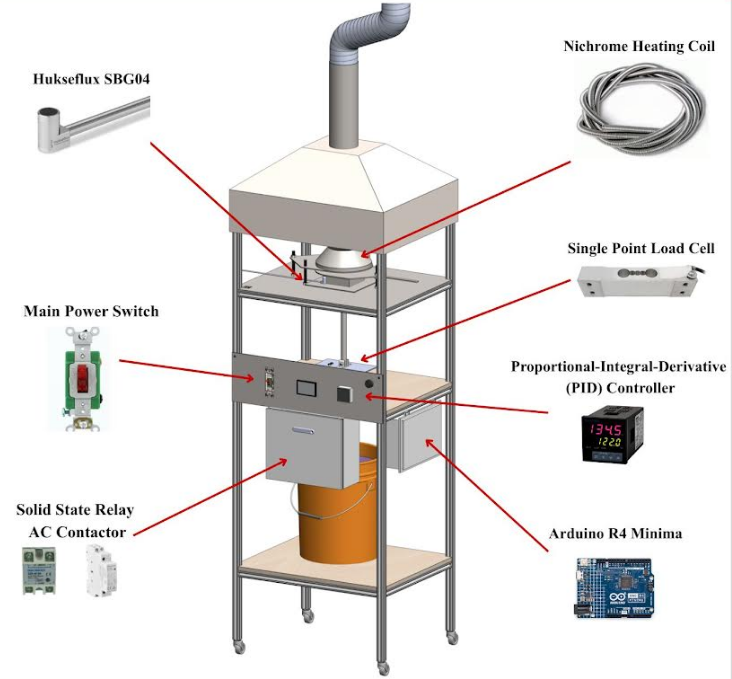

California faces increasingly frequent and severe wildfires, making accurate

vegetation flammability data essential for modeling fuel behavior and improving fire

management strategies. However, commercial cone calorimeters are costly and

difficult to adapt for specialized research. The FIAMMA lab directed by Dr. Carmignani was in need of a cone calorimeter that is affordable, portable, and customizable in order to conduct flammability tests on vegetation samples for wildfire research. To make the cone calorimeter reliable to similar research conducted, it closely adheres to the ISO 5660 and ASTM E1354 standards for cone calorimeter testing. To achieve the desired heat flux of 50 kW/m2, the cone calorimeter uses a heating coil powered by 250V AC operated by a Proportional-Integral-Derivative (PID) controller delivering current up to 15 amps. Additionally, it is equipped with various sensors to measure mass loss, heat flux, temperature and gas emissions as testing is being conducted.

- Team Members: Emily Halsey, Diana Chavez, Olivia Towers, Yani Ochoa, Liam McCarty

Current methodologies for biopolymer fiber production, particularly those imitating natural processes such as spider silk formation, are unable to integrate precisely controlled systems capable of transforming biopolymer solutions into continuous

fibers through coagulation baths. Traditional methods rely on manual intervention or non-optimized systems that result in inconsistent fiber characteristics such as variable diameters, weak mechanical strength, and irregular morphology. This presents a significant challenge in the biomaterials field, where exact control over fiber extrusion and tension is critical. There is currently no well-documented system that seamlessly combines the extrusion of biopolymer solutions via a microfluidic chip with synchronized fiber collection and processing mechanisms. Specifically, the absence of an automated system capable of efficiently extracting and processing biopolymer solutions into fibers through a set of coagulation baths.

- Team Members: Daniela.Lopez, Emily Sok, Chase Ketterling, Francisco Botello

Solar panels lose up to 25% efficiency when heated. Icarus RT designs heat exchangers that attach to and cool panels, improving power and delivering hot water. Icarus RT needs a Control and Monitoring System for their residential heat exchangers.

- Team Members: Morgan Sanford, Timothy Shargel, Ivan.Martinez

The goal of the design is to develop a new forearm support module to add to the existing airframe exoskeleton support by Levitate Technologies.

- Team Members: Jason Prom, Ashley Chau, Edgar Romero, Jeremy Cruz, Ricardo Angulo, Veronica Solorzano-Ramirez

In collaboration with Dr. Wenwu Xu, our team was responsible for developing a

fast heating furnace for use in a Scanning Electron Microscope (SEM). The system is

designed to rapidly reach high temperatures.

- Team Members: Pablo Hinojosa Amaya, Brian Riley, Gabriel Schauer, Adrian Hidalgo

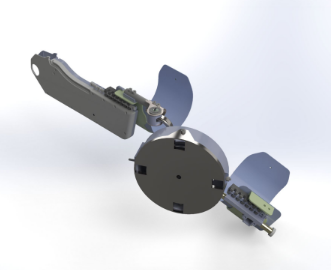

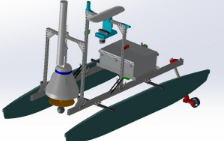

The GUS-V is a remotely-operated ocean surface vessel with a limited radio communication range. The solution is a buoy, housing radio relay equipment, that can be deployed from the GUS-V to extend its effective range.

- Team Members: Robert Davidowitz, Simhal Maharaj

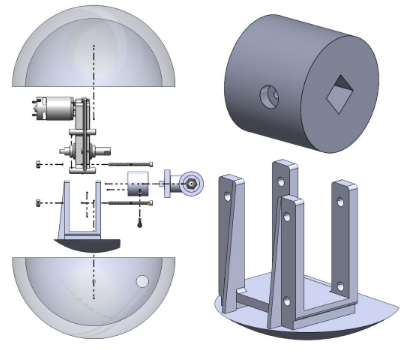

NIWC has a data collection device deployed up to 2000 meters deep in the

ocean that surfaces at a set time and transmits data. We were to design and

integrate a system to remotely sink and destroy any electronics within the device,

removing the need for manual retrieval. The design is to be able to survive ocean

conditions, operate covertly, and have minimal environmental impact.

- Team Members: David Meyer, Ryan Chen, Juan Lomeli, Emily Gornall, Zuadi Farah

Phyn develops devices that measure temperature, pressure, and flow rate in a homes pipes. Using pressure measurements, these devices can detect

leaks. Currently, these devices can only detect leaks from inside the home, not leaks from the irrigation system. This is because the Pressure Reducing

Valve (PRV) blocks sound waves, created by changes in water pressure, from reaching the Phyn device.

- Team Members: Ty Kim, Evan Ansgarius, Austin McDowell