Research Laboratories

Dr. Yang Yang’s research focuses on the machine, materials, and structure development for bioinspired 3D printing. His work includes 3D printing of bioinspired lightweight and strong smart composites for wearable sensor, Piezoelectric composites for ultrasound devices and energy harvesting, bioinspired microscale for surface/interface applications, 3d printing of self-healing and recycle composites for smart devices such as robotics.

The Advanced Manufacturing for Energy Devices (AMED) Lab at San Diego State University (SDSU) focuses on cutting-edge manufacturing methods for the fabrication of advanced functional materials with broad applications in energy conversion and storage, sensing, and wearable/flexible electronics.

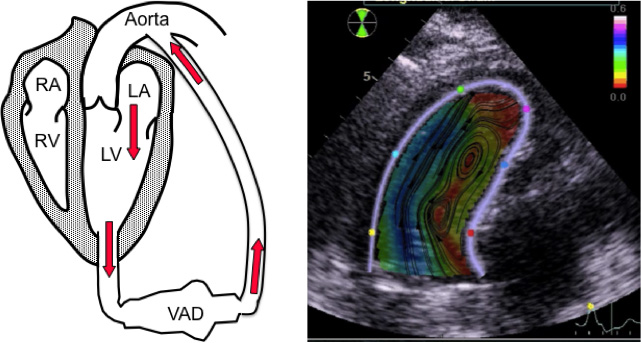

The Bioengineering Laboratory located in E 329, has 800 ft2 of space in the SDSU Engineering Building and serves as both an instructional and research laboratory. Two workstations equipped with the BIOPAC instructional lab system provide “hands-on” experiences for approximately forty Biomechanics (ME 580) students each year. Ten-twelve undergraduate and graduate students also work on research projects each year in the area of cardiovascular biomechanics, biomaterials and medical devices.

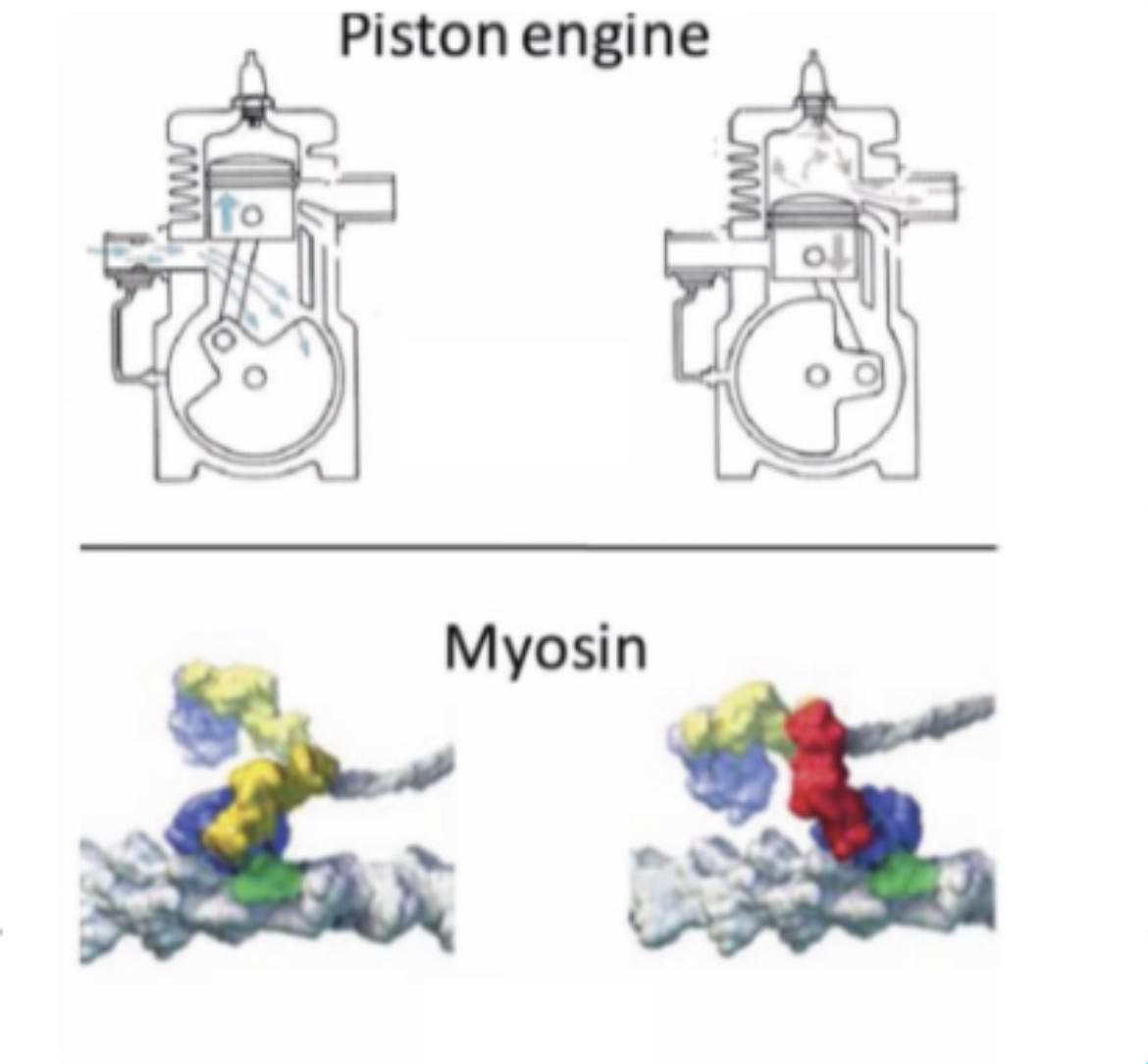

Computational Active Matter Mechanics

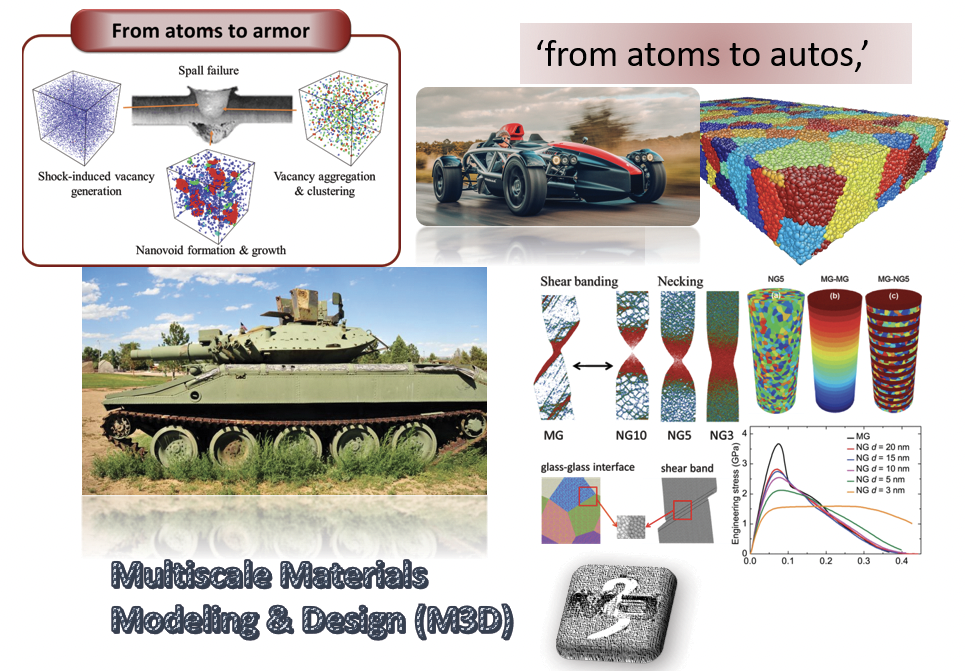

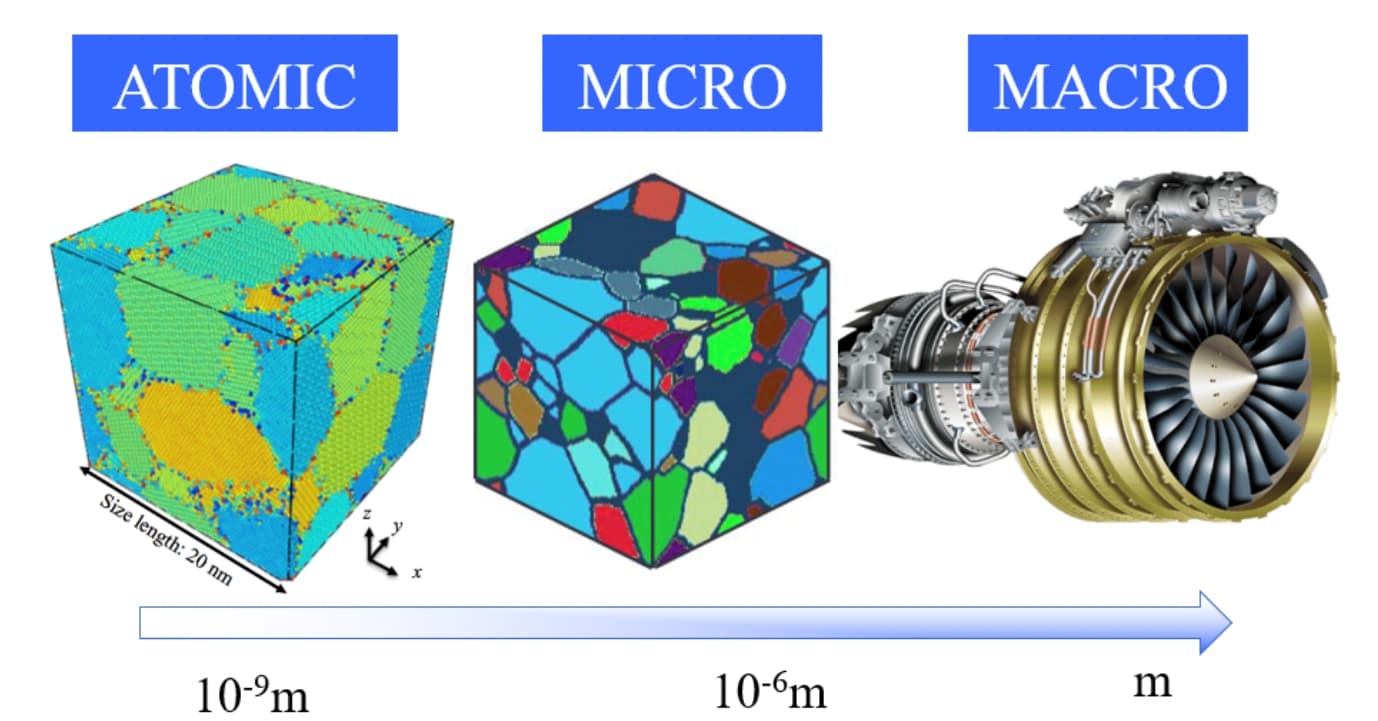

At Computational Mechanics Lab (CML), we're at the forefront of materials informatics, utilizing cutting-edge approaches to discover & design novel materials with exceptional properties. Our research revolves around computational mechanics, atomistic modeling, and data-driven techniques – all aimed at advancing the development of groundbreaking technologies across various domains, including transportation, medicine, energy, and security. We explore the intricate world of data-driven & physics-based multiscale material modeling to drive innovation in material design, discovery, processing, characterization, & applications of advanced materials.

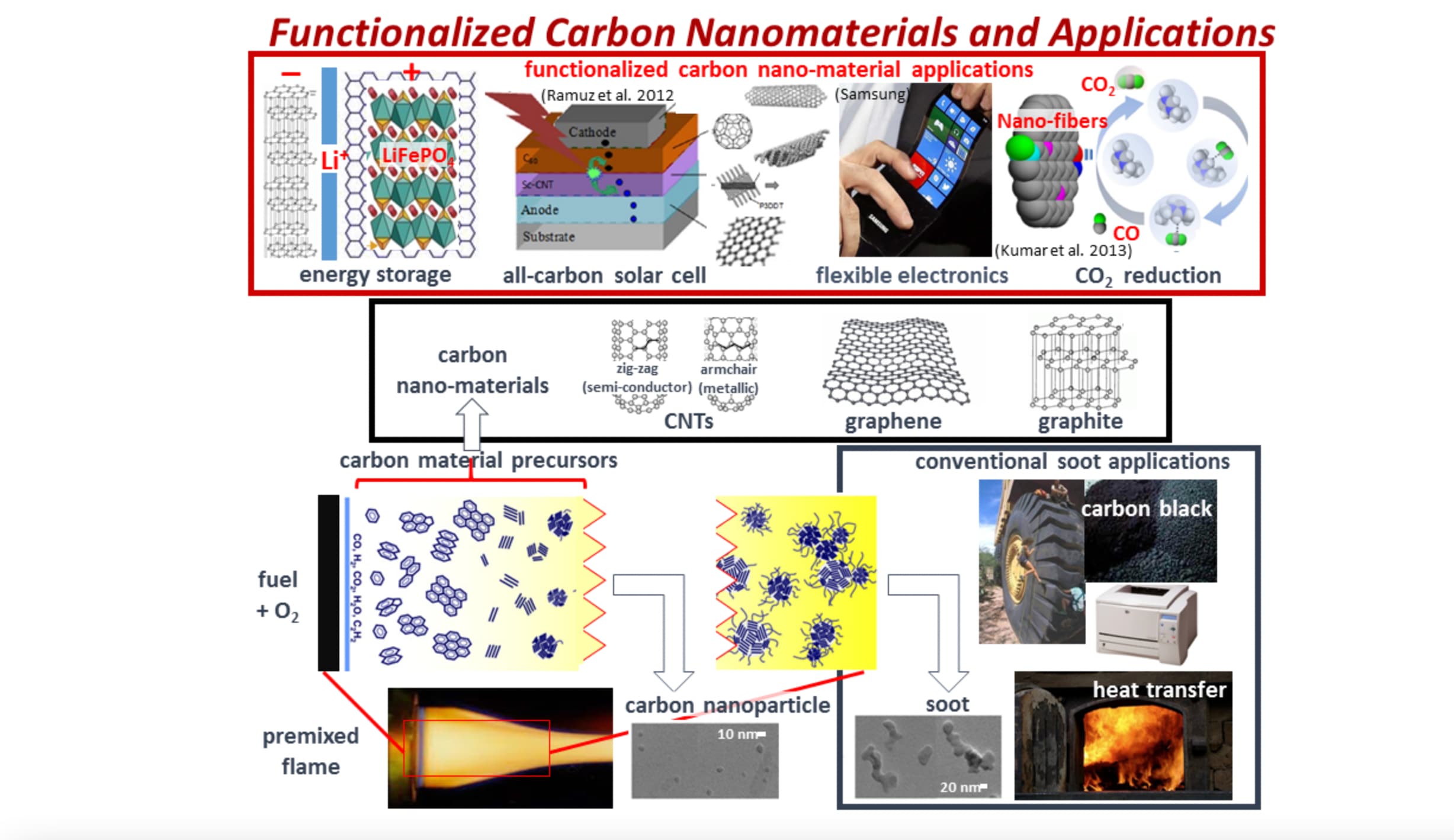

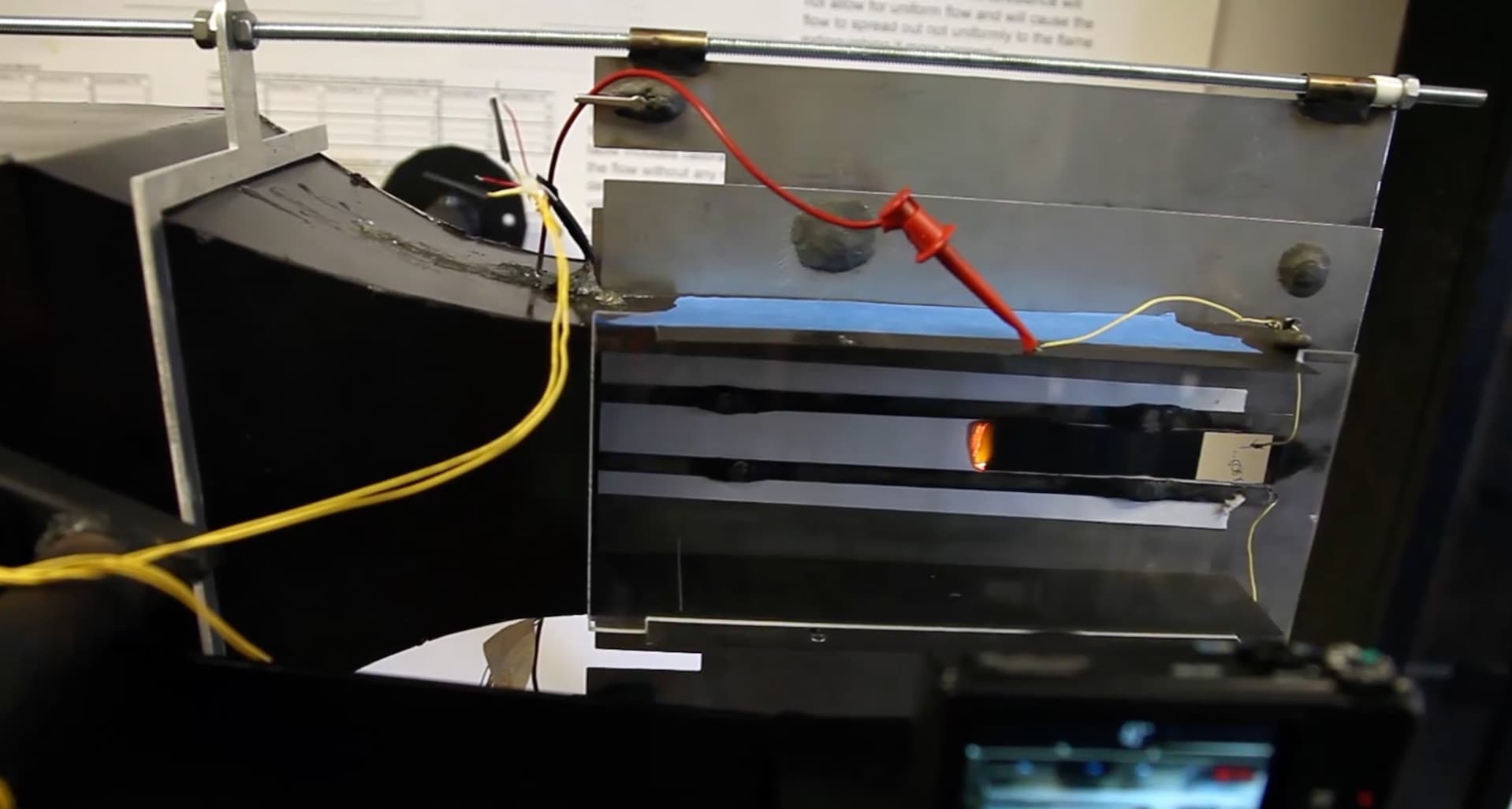

The Combustion and Solar Energy Laboratory, located in EIS 211, provides research space for projects involving flammability testing and solar energy conversion. Undergraduates working on Senior Design projects and graduate students have helped outfit the lab with several pieces of unique equipment. Two material flammability test rigs were constructed to measure the burning rates of various materials to be used aboard spacecraft, such as composites and fabrics. The apparatuses are unique in their ability to recreate space craft atmospheres and flow patterns, especially by reducing the effects of buoyancy that we have on earth but that are not present on space craft. Another apparatus was built to pyrolyze methane at high pressure and temperature to create a carbon particle suspension to act as a high temperature solar absorbing medium. Additional combustion and solar projects include an apparatus to monitor wind speeds and their effect on wildfires, a solar air conditioner using a donated evacuated tube array, and a solar Stirling engine with a 1.8 m parabolic dish. Additionally, NASA has donated an optical table, a particle image velocimetry laser to use with a high megapixel camera we purchased, and various other components and tools to outfit the laboratory.

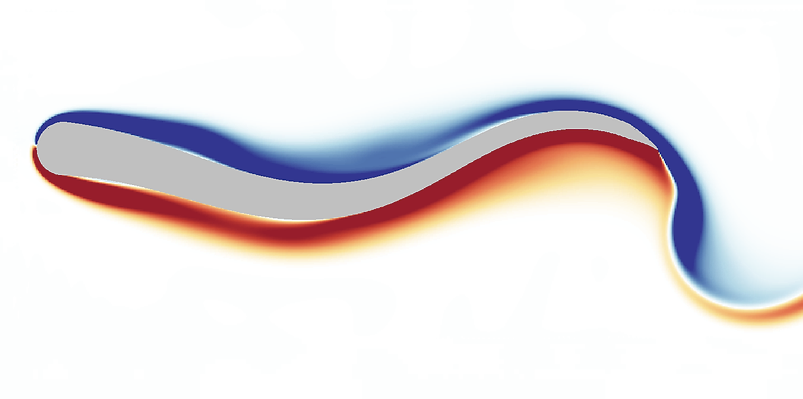

Welcome to Dynamic Systems and Control Laboratory (DSCL)! The lab focus is on a wide range of research efforts which include, but are not limited to, Nonlinear Modeling, Dynamic Analysis, Optimization (design, operation, and control), and Centralized/Decentralized Control of Multi-Robot Systems, Smart Flow Distribution Network, Magnetic Bearings, and Large-Scale Systems. Multidisciplinary systems have received much attention with respect to their complex physics leading us to develop efficient numerical and analytical tools along with experimental work to translate the ambiguous behaviors of these systems to understandable mathematical language.

Dynamic Systems and Intelligent Machines Lab is focused on the science of autonomy and producing advanced perception, control, planning, and decision-making techniques to enable robust operation of intelligent unmanned vehicles in spatially and temporally dynamic and uncertain environments.

This is a center for research on energy efficiency and renewable energy. Facilities include equipment for studying waste heat recovery, especially low-grade heat recovery, and organic Rankine cycles. Wind turbine facilities are employed for studying morphing blades for wind and wave energy applications. Combined heat and power systems (CHP) are available for ultra-low grade heat recovery, including recovery of waste heat from an automobile engine to run an ammonia-based absorption chiller.

Energy FANS Laboratory located at E425 A&B, is equipped with a power meter, flow meter, RMP meter, DAS, a combustion analyzer, and other thermal equipment.

Experimental Mechanics Laboratory Experimental Mechanics Laboratory (EML) was established in January 2012 to conduct basic and applied research in the area of mechanics of nontraditional materials. Specifically, our research is focused on the mechanics of polymers, composites and smart materials.

The Fire Research Laboratory located in E 331, is linked to the Thermal Science courses ME 350, 351, 653. It is equipped with a Flame Tracker which is an innovative combustion experimental set up devised at SDSU. To overcome the difficulty in studying a spreading flame, the Flame Tracker moves the fuel at exactly the same velocity of the propagating flame in the opposite direction. The flame, therefore, becomes stationary in the laboratory coordinates and can be photographed and probed.

The Interfacial Design Laboratory is focused on developing and disseminating cutting edge research in the areas of renewable energy, electrochemistry, and corrosion prevention. Our strategy is to develop and utilize novel characterization methods to clearly understand reasons of failure, inefficiency and poor performance. Using this foundation we then design rational solutions to challenges facing society.

The Micro-Electro-Mechanical Systems Laboratory (MEMS Lab) is equipped with Photoresist Spinner, UV Light Source, and CCD Camera and Stereomicroscope System and various microfluidic equipment for soft lithography and microfabrication.

Multiscale Modeling of Materials

The Computational Reaserch Laboratory located in E 327, provides research space relating to the area of Multiscale Modeling of Materials.

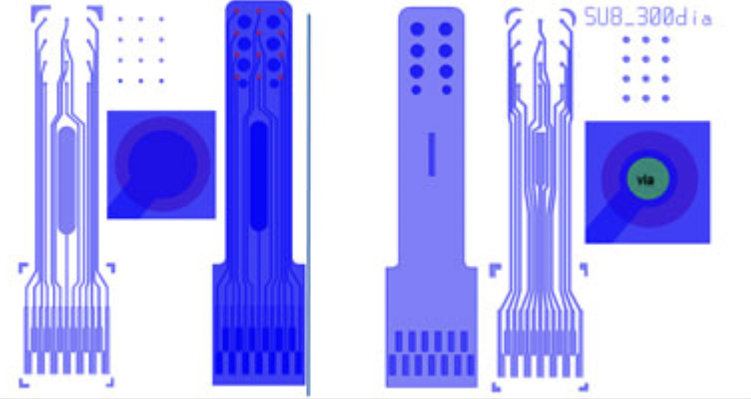

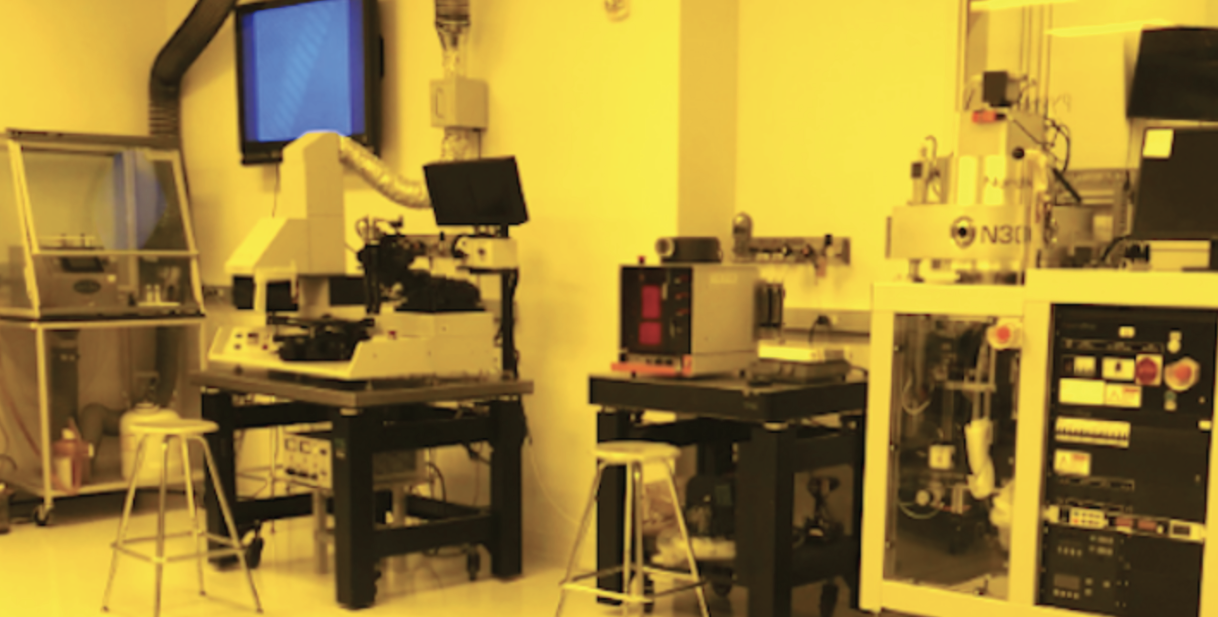

NanoFab

Welcome to NanoFab.SDSU, a brand-new leading center for micro and nanofabrication located in the EIS building of SDSU. The state-of-the-art facility has a 2500 sq. ft. ISO 9001-certified Class 1000 Cleanroom with 4” and 6” wafer processing capability with 0.2 micron lithography feature sizes. The Center provides a comprehensive and expanding selection of state-of-the-art process equipment for lithography, etching, thermal processing, thin-film deposition, and characterization.

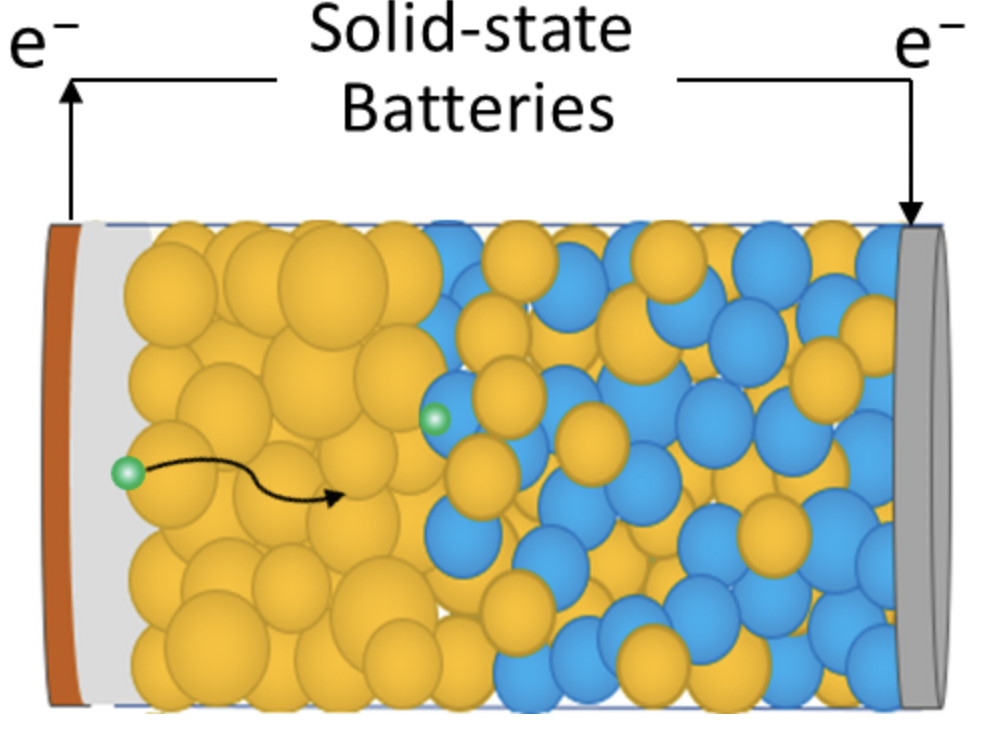

Electrochemical Energy (e2) Lab at SDSU focuses on establishing the scientific foundation and prototype material systems for the next-generation of high-energy and high-power electrochemical energy storage devices.

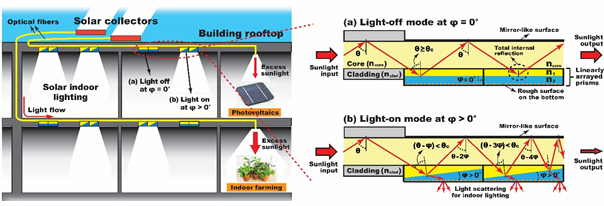

Our research focus is not only on investigating fundamentals of small-scale fluidic and interfacial phenomena such as electrowetting, triboelectricity, and micro/nanofluidic interaction with photonics, but also developing novel nanomaterials and integrated micro/nano systems for following applications: optics applications, energy applications, bio and environmental applications.

The Powder Technology Laboratory (PTL) is linked with the courses ME 645 and ME 646 and is equipped with sintering furnaces, pressing equipment, analytical instruments for material characterizations of different kinds, a SPS machine, optical microscopes, and other state of the art equipment.

SmartHealth Laboratory

This Laboratory is equipped to support the transdisciplinary research that focuses on developing next generation health sensor technologies ranging from portable, wearable and minimally intrusive sensors that can provide real-time health monitoring. The laboratory equipment includes instruments for designing, testing, and evaluating sensors, integrated circuits, computer networks, signal analysis, precision measurements, and performance verification. The laboratory also has AFM, desktop SEM, and a nanoindenter. The list of other major equipment available in the laboratory is as follows: KEPKO hi-current computer controllable DC power supply, EG&G lock-in amplifier, LION capacitance-displacement sensor, Trinocular boom microscope with CCD camera, Newport Vibration isolation table, KEPKO hi-voltage DC power supplier, Acopian hi-voltage DC power supply, HP signal generator, digital oscilloscopes, frequency counter, Olympus NDT ultrasonic pulsar/receiver, Olympus NDT ultrasonic transducer, and HP impedance analyzer.

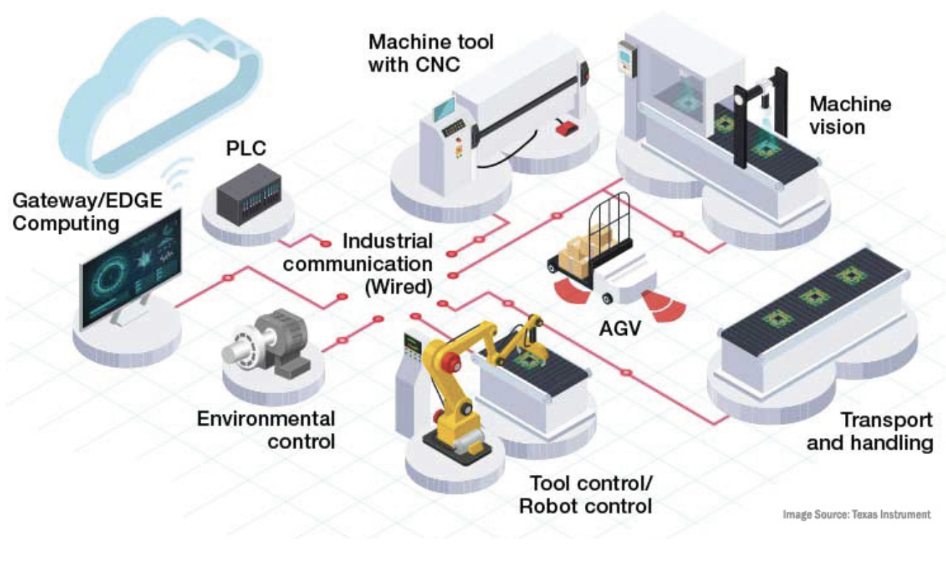

Smart Manufacturing and Metrology's (SMM) goal is to lead research on intelligent and integrated metrology and sensors for smart manufacturing. We mainly study machine learning, cyber physical systems, optical metrology, machine vision, and mechatronics techniques for real-time defect detection and control of advanced manufacturing processes such as 3D printing, which is a critical enabler of industry 4.0.