Dr. Elisa Torresani and Dr. Eugene Olvesky

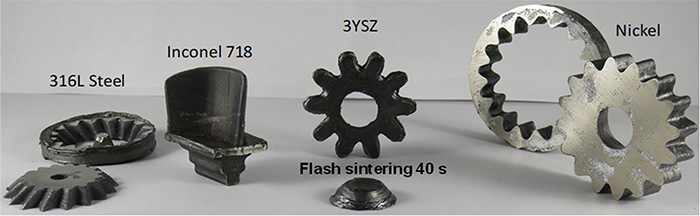

Recent investigations conducted at SDSU showed that the advanced materials manufacturing efficiency can be dramatically improved by enabling an ultra-rapid “flash” regime of processing when complex shape components with unique properties can be fabricated in a matter of a few seconds. This new processing technology, named “Flash Spark-Plasma Sintering” represents a technological breakthrough in manufacturing of ceramic, metallic, and composite materials. These unprecedented technological advances have been recently featured in Nature Scientific Reports and multiple press releases.

In addition, SDSU researchers discovered new ways of manufacturing net-shape components from hard-to-deform materials using a combination of additive manufacturing (3D-printing) and spark-plasma sintering of ceramic and metallic parts.

The main objective of this project will be determination of optimal processing technique(s) and condition(s) that result in near-shaped bulk nanostructured materials using the above-mentioned novel manufacturing technologies. The powders to be tested will be developed and provided by Cerion. This project will focus on optimizing processing conditions for two nanostructured materials systems: boron carbide and tungsten carbide.